The sputtering target is an important material for physical vapor deposition, the most widely used technology for depositing materials. As its name suggests, “physical” means that the PVD coating method involves a purely physical process. During the physical vapor deposition, a solid target material is broken up into the vapor state (usually in a high vacuum environment), and then deposited on other materials (known as the substrate) to form a film.

In short, the film materials are transferred via various methods from some starting ‘target’ with subsequent condensation onto the host substrate. The films made of the sputtering targets by physical vapor deposition technique have many advantages, such as superior hardness, durability and good resistance to tarnishing and corrosion enabling. Therefore, PVD thin films have been more and more used for multiple purposes nowadays and the demand for sputtering targets has also increased rapidly. Let’s take a look at the applications of the sputtering target for physical vapor deposition.

Decorative Coating

Decorative coating mainly refers to the surface coating of mobile phones, watches, glasses, sanitary ware, hardware parts, and etc. to make them look more beautiful. PVD Coating is widely used for decorative purpose due to the various metallic colors of pure metal sputtering target or alloy sputtering target. For examples, TiN sputtering film has the noble gold color, Cr2N sputtering film has the beautiful silver color. Other special colors are also available by PVD coating, such as rose gold, smoke grey, purple bronze and etc.

Decorative coating mainly refers to the surface coating of mobile phones, watches, glasses, sanitary ware, hardware parts, and etc. to make them look more beautiful. PVD Coating is widely used for decorative purpose due to the various metallic colors of pure metal sputtering target or alloy sputtering target. For examples, TiN sputtering film has the noble gold color, Cr2N sputtering film has the beautiful silver color. Other special colors are also available by PVD coating, such as rose gold, smoke grey, purple bronze and etc.

Read more about sputtering targets used for decorative coating.

Optical coating

PVD coating used in optical coating includes anti-reflection coating in cameras, high-reflection coating in solar receiver, low-emission coating for glass, and etc. Take the low-e glass for an example, it can reflects heat back to its source and keeps the room stays cooler in the summer and warmer in the winter, it helps protect against UV fading and it requires no special cleaning. Therefore, low-e coated glass has recently replaced traditional architectural glass. And almost all large glass processing companies are rapidly increasing the glass coating line. Correspondingly, the demand for sputtering targets has also increased rapidly.

PVD coating used in optical coating includes anti-reflection coating in cameras, high-reflection coating in solar receiver, low-emission coating for glass, and etc. Take the low-e glass for an example, it can reflects heat back to its source and keeps the room stays cooler in the summer and warmer in the winter, it helps protect against UV fading and it requires no special cleaning. Therefore, low-e coated glass has recently replaced traditional architectural glass. And almost all large glass processing companies are rapidly increasing the glass coating line. Correspondingly, the demand for sputtering targets has also increased rapidly.

Sputtering targets used for optical coatings are: chromium (Cr) sputtering target, nickel-chromium (NiCr) sputtering target, zinc-tin (ZnSn) sputtering target, etc.

Protective Coating

Protective coating, which is easy to understand, is coated on the substrate to protect it and extend its service life. Protective films include corrosion protection film, lubricant film and thermal protective film. TiC sputtering film and BN sputtering film are frequently used as hard film in cutting and abrasive tools.

Protective coating, which is easy to understand, is coated on the substrate to protect it and extend its service life. Protective films include corrosion protection film, lubricant film and thermal protective film. TiC sputtering film and BN sputtering film are frequently used as hard film in cutting and abrasive tools.

Sputtering targets used for protective coatings are: titanium aluminum (TiAl) sputtering target, aluminum chromium (AlCr) sputtering target, titanium (Ti) sputtering target,etc.

Electrical Coating

![]() Electronics industry develops fast and requires high purity and large quality materials. Sputtering targets can be used to produce conductive materials and dielectric thin film in semiconductor devices and integrated circuits, superconducting thin film and ITO Film.

Electronics industry develops fast and requires high purity and large quality materials. Sputtering targets can be used to produce conductive materials and dielectric thin film in semiconductor devices and integrated circuits, superconducting thin film and ITO Film.

Read more about ITO film.

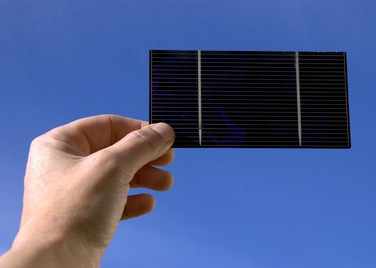

Solar Cell Coating

At present, solar cells have developed to the third generation. The first generation is monocrystalline silicon solar cells, the second generation is amorphous silicon and polycrystalline silicon solar cells, the third generation is thin film solar cells (represented by copper indium gallium selenide CIGS film), and the sputter coating process is the preferred preparation method.

At present, solar cells have developed to the third generation. The first generation is monocrystalline silicon solar cells, the second generation is amorphous silicon and polycrystalline silicon solar cells, the third generation is thin film solar cells (represented by copper indium gallium selenide CIGS film), and the sputter coating process is the preferred preparation method.

The main types of targets used for Solar cell coating are: zinc oxide (ZnO) sputtering target, zinc aluminum (ZnAl) sputtering target, cadmium sulfide (CdS) sputtering target, etc.

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputtering targets such as metals, alloys, oxides, ceramic materials.

For helps for your coating projects, please contact us or leave us a message.

For sputtering target price, please send us an inquiry.