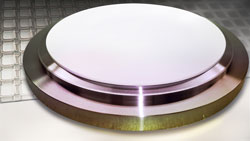

Indium is a soft metal with a low melting point and excellent thermal and electrical properties, which make it the preferred method for bonding sputtering targets.

– Indium has the best thermal conductivity

– Indium bonding is one of the most efficient target bonding services at drawing heat away from the target.

– Indium is more malleable than other bonding solders.

– It reduces cracking that is caused by the mismatch in the thermal expansion coefficients of the target and backing plate

| Maximum Operating Temperature (°C) | 150° C |

| Thermal Conductivity (W/mK) | 83 |

| Coefficient of Thermal Expansion (K-1) | 32.1 x 10-6 |

| Electrical Resistivity (ohm-cm) | 8 x 10-6 |

| Bond Coverage | >95% |

| Bond Line Thickness | 0.010″ ± 0.003″ |

| Target Size | Target Material | Part No. |

| 1″ to 2″ Diameter | Metal or Ceramic | EJBONDMET1 |

| 3″ to 4″ Diameter | Metal or Ceramic | EJBONDMET3 |

| 5″ to 6″ Diameter | Metal or Ceramic | EJBONDMET5 |

| 7″ to 8″ Diameter | Metal or Ceramic | EJBONDMET7 |