Rotatable sputtering target technology is pivotal in thin-film deposition, particularly for large-area coatings such as architectural glass and flat-panel displays. Common manufacturing techniques include plasma spraying, casting, and extrusion of the complete assembly.

Compared to planar targets, rotatable targets contain more material and offer significantly higher utilization. This results in extended production runs, reduced system downtime, and increased coating equipment throughput. Additionally, the rotating mechanism distributes heat buildup evenly across the target surface, enabling operation at higher power densities. This leads to increased deposition rates and enhanced performance in reactive sputtering processes.

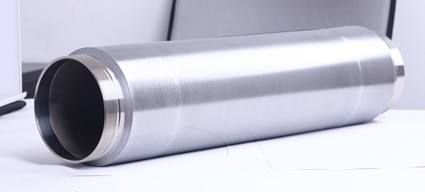

Stanford Advanced Materials (SAM) supplies custom-made cylindrical rotatable sputtering targets in a wide range of materials, including Cr, Ti, Cu, Mo, Nb, Ag, Al, Si, Sn, W, Ta, stainless steel, and other metals and alloys.

Sprayed Targets: We offer thermally sprayed rotatable targets—via plasma, arc, or cold spray methods—that ensure process stability and high performance. Available materials include AZO, ITO, Mo, Si, TiO<sub>x</sub>, ZnO, and ZTO.

Cast Targets: Our cast targets deliver high compositional and microstructural homogeneity with precise purity control, contributing to high process yield and long service life. Typical products include InSn, Sn alloys, ZnAl, and ZnSn.

Extruded Targets: SAM is a trusted supplier of high-purity extruded rotatable targets in Al, Cu, Mo, Nb, Ta, Ti, V, and other materials, with well-controlled grain size and purity.

HIP/Sintered Targets: We provide hot-isostatically pressed (HIP) and sintered rotatable targets in materials such as Cr, Mo, ITO, AZO, and ZnO.

Browse our full range of high-performance rotatable sputtering targets tailored to diverse coating applications.