Basic Principles of PVD Technology

Physical Vapor Deposition (PVD) technology hinges on a meticulously orchestrated three-step process, each phase crucial to achieving the technique’s renowned benefits, from durability to environmental friendliness. Understanding these steps elucidates how PVD transcends traditional coating methods, offering unparalleled precision and versatility. Here’s a closer look at each stage:

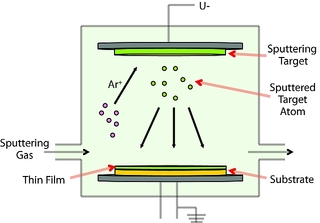

- Gasification of the Plating Material: The journey begins with transforming the coating material into a gas. This is accomplished through evaporation or sputtering, processes that dislodge atoms or molecules from the material, converting them into a vapor without altering their chemical composition. This phase sets the stage for the material’s transport and eventual deposition.

- Migration of Plating Atoms, Molecules, or Ions: Once vaporized, these particles embark on their migration toward the substrate. This movement is not merely physical but involves intricate dynamics as the particles interact, propelled by the forces exerted in the vacuum chamber. Despite potential collisions and interactions, the integrity of the particles remains intact, ensuring that the deposition material reaches the substrate as intended.

- Deposition on the Substrate: The culmination of the process is the deposition of these particles onto the substrate, where they adhere and form a cohesive film. This stage is marked by the precise accumulation of the vaporized material, layer by layer, onto the substrate. Significantly, this deposition process is purely physical, involving no chemical transformations or the creation of new substances.

Each step of the PVD process is engineered to maintain the purity of the coating material and ensure its uniform application, highlighting PVD’s capacity to produce coatings of superior quality and performance. This foundational understanding of PVD’s basic principles underscores the technology’s advantages and its role in advancing coating applications across industries.

Advantages of PVD Coating Over Other Methods

PVD technology stands out in the surface coating industry for its unique advantages over traditional methods like electroplating and painting. These benefits range from enhanced durability and environmental friendliness to versatility in application and ease of maintenance, making PVD a preferred choice for various industries.

Good Durability

PVD coatings excel in durability, providing superior hardness and resistance to wear and corrosion when compared to other coating methods. This is particularly beneficial in applications where longevity and resistance to harsh environments are critical. For instance, tools and components in the automotive and aerospace sectors benefit significantly from PVD coatings, as they maintain their integrity and performance over extended periods, even under extreme conditions. The molecular bond formed between the coating and the substrate through PVD ensures a durable finish that withstands physical impacts and chemical exposures far better than traditional coatings.

Wide Application

The versatility of PVD technology is evident in its wide range of applications. It can apply coatings to nearly all types of inorganic and some organic materials, accommodating a diverse array of substrates and surfaces. This flexibility allows for a variety of finishes, from glossy to matte, catering to industries as varied as electronics, medical devices, and fashion accessories. The ability to coat different materials with precision ensures that PVD can meet the specific requirements of each application, whether it’s enhancing the aesthetic appeal of jewelry or improving the functional performance of surgical instruments.

Environmentally Friendly

PVD offers significant environmental advantages over conventional coating techniques. Operating in a vacuum environment, the PVD process eliminates the risk of releasing harmful gases, such as carbon monoxide (CO) or sulfur dioxide (SO2), into the atmosphere. This makes it a cleaner, safer alternative that aligns with increasing regulatory and consumer demands for environmentally sustainable manufacturing practices. By minimizing hazardous waste and reducing the need for chemicals used in processes like electroplating and painting, PVD represents a greener solution for surface coating.

Convenient Cleaning

Maintenance and cleaning are more straightforward with PVD-coated products. The smoothness and resistance to tarnishing of PVD coatings mean that items like watches, jewelry, and decorative pieces can be easily cleaned with a soft cloth or glass cleaner, without the need for harsh chemicals or extensive polishing. This not only saves time and reduces maintenance costs but also prolongs the aesthetic appeal and functional life of the coated items.

High Quality and Multiple Choices

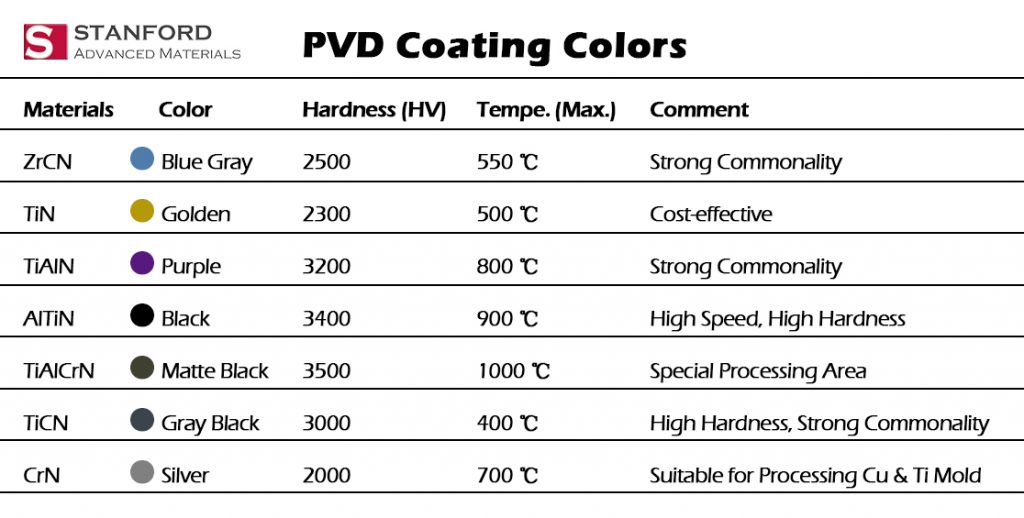

PVD coatings are renowned for their high quality and the wide variety of color options they offer. The process allows for precise control over the thickness and composition of the coating, resulting in a fine, smooth finish that is rich in metallic luster and resistant to fading. From golden yellow (TiN) and bright silver (CrN) to purple (TiAlN), the range of colors available through PVD enables manufacturers to meet specific design requirements, offering consumers more choices and enhancing the marketability of the products.

Importance of Material Quality

The superiority of Physical Vapor Deposition (PVD) coatings is intrinsically linked to the quality of the sputtering targets or evaporating materials used. High-quality materials are foundational for leveraging the full advantages of PVD, such as enhanced durability, environmental sustainability, and aesthetic appeal. These materials ensure the deposited films are uniform, compact, and exhibit strong adhesion to substrates. Without consistent quality in these raw materials, attaining high-quality, reliable films becomes a formidable challenge.

In this context, sourcing from reputable suppliers like Stanford Advanced Materials becomes essential. Their provision of superior sputtering target materials directly contributes to the effectiveness and efficiency of the PVD process. This relationship between material quality and coating excellence underlines the importance of careful selection of materials and suppliers in achieving the desired outcomes of PVD coating applications, ensuring that the technology’s potential is fully realized.