See our Copper Sputtering Product

Copper sputtering targets are excellent sputtering materials in the vacuum coating industry. Sputtering targets are a special group of materials, especially for thin-film coating. The copper sputter target is a product of high-purity copper metal after a series of processes. It has specific dimensions and shapes.

Since high-purity copper has many excellent properties, copper targets have been widely used in cutting-edge fields such as electronics, communications, superconductivity, and aerospace.

Are you curious about how copper metal becomes Cu sputtering targets? Do you want to know the specifications and applications of copper sputter coater targets?

Copper Sputter Target Production Processes

How to Make Copper Sputter Target – Step 1

The first step in transforming metal to a Cu sputter target is smelting. Copper ore, which can be divided into three categories, is the raw material for copper smelting.

- Sulfide ore: chalcopyrite (CuFeS2), porphyrite (Cu5FeS4) and chalcopyrite (Cu2S).

- Oxidized ore: cupro ore (Cu2O). malachite, [Cu2(OH)2CO3], chrysocolla (CuSiO3·2H2O).

- Natural copper

Among different types of copper ores, the ore with a copper content of about 1% (0.5% to 3%) is worth mining. As for these ores, some impurities such as gangue can be removed by flotation, and it is easy to obtain the ore concentrate with a high copper content (8% to 35%). After extraction, crude copper is obtained, and the copper is purified from 99.95% to 99.99%, 99.999%, and 99.9999% by multiple electrolysis and regional melting methods.

How to Make Copper Sputter Target – Step 2

The next series of steps include forging, rolling, and heat-treating high-purity copper ingots in raw materials. The purpose is to make the crystal grains in the copper ingot smaller and increasing in density to meet the requirements of copper targets required for sputtering.

How to Make Copper Sputter Target – Step 3

After the deformation treatment, the high-purity copper sputtering material is machined to achieve high precision and high surface quality and to fit the size for the vacuum coater.

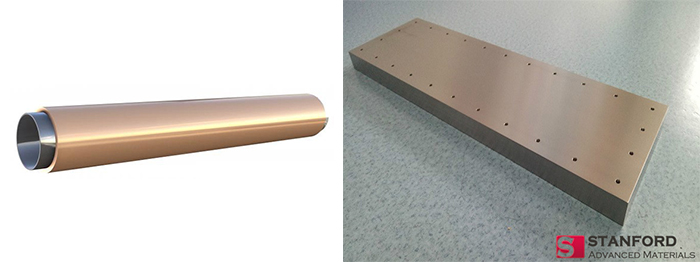

Usually, there are planar copper sputtering targets and rotary copper sputtering targets. Other customized shapes of sputtering materials are also available.

Copper Sputter Target Physical Specifications

Copper Sputtering Target Physical Properties

| Chemical Formula | Cu |

| Purity | 99.9%, 99.99%, 99.999% |

| Shape | Discs, Plates, Column Targets, Step Targets, Custom-made |

| Color/Appearance | Copper, Metallic |

| Density | 8.92g/cm3 |

| Melting Point | 1083.4℃ |

| Boiling Point | 2567℃ |

Copper Sputtering Target Classification

As we mentioned above, copper targets are often divided into planar copper targets and rotatory copper targets. Planar targets are sheet-shaped, with round and square types. The rotatory target is tubular, and the utilization efficiency is high. The rotary copper target product can be finally obtained through various processes such as high-purity copper extrusion, stretching, straightening, heat treatment and machining.

Copper Sputter Target Application

Copper sputtering target is suitable for DC two-pole sputtering, three-pole sputtering, four-pole sputtering, radio-frequency (RF) sputtering, ion beam sputtering, magnetron sputtering, etc. It can be used to coat reflective films, conductive films, semiconductor films, capacitor films, decorative films, protective films, integrated circuits, displays, and so on. Compared with other targets, such as titanium sputtering targets, the price of copper targets is much lower. Therefore, the copper target is the preferred sputtering material under the premise of meeting the requirements of the film layer.

Thanks for reading this passage and hope that you now have a basic understanding of copper sputter targets. Stanford Advanced Materials (SAM) is a leading sputtering target manufacturer based in Lake Forest, California. If you feel interested about the copper sputtering target, you can go to our product page for more information, or directly send us an inquiry. You can also contact us via target@samaterials.com. Free samples are available.

Inquiry SAM's copper sputter targets