3D printing has evolved over the past few years, meaning that several things have changed, particularly, the type of products obtainable at the end of the process. The products of 3D printing are as diverse as the many materials used in printing them. Before 3D printing can be realized, you must send a detailed image of the design to the printer.

The details of the image are rendered in standard triangle language (STL). This carries all the attributes of a given design to the printer. And with a computerized 3D printer, you can see each design from all sides and angles. Here are the best and most common materials used in 3D printing.

Plastic

Plastic happens to be one of the most advanced materials for printing 3D Toys and several other household fixtures. Of all the materials used for 3D printing, plastic is the most common. The reason why plastic is a popular choice is not far-fetched, considering its flexibility, transparency, multiple bright colors, and shiny texture.

Common items of plastic 3D printing include desk features, vases, cogwheels, bracelets, utensils, etc. These materials or products could also be transparent like others. Most plastic products are made with FDM printers. In this case, thermoplastic filaments are melted and molded into shape, one layer after another. The types of plastic used in this process are usually made from one of the following materials:

- Polylactic acid (PLA)

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate (PC)

- Polyvinyl Alcohol Plastic (PVA)

Powder

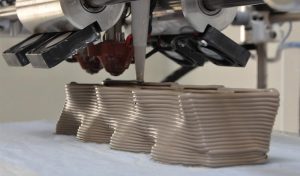

Recently, powdered materials have become another important resource for making 3D-printed products. In fact, many state-of-the-art 3D printers of today, use 3d printing powder in constructing products. Typically, the powder is melted and distributed in layers right inside the 3D printer. This is continued until the operator achieves the desired thickness, texture, and patterns.

Since powdered materials allow for a high level of detail on 3D-printed materials. The powders used in 3D printing can be obtained from a variety of sources and materials. Here are the most common ones:

- Polyamide (Nylon), and

- Alumide

Metals

Metal 3D printing is white popular, as it has been used in many components construction processes, including the manufacture of travel equipment, jewelry, and in the aerospace industry. Aside from plastics, metals are the second-most commonly used 3D printing materials. They are used in a process known as direct metal laser sintering (DMLS). Compared to the other processes and materials, 3D printing produces strong and durable materials.

Here are some examples of metals applicable to the DMLS technique:

- Aluminum

- Steel

- Iron

- Gold

- Nickel, and

- Bronze

Carbon Fiber

When plastic 3D printing materials are used, carbon fiber composites can be used as a top-coat in the 3D printer over plastic materials. Interestingly, this combination makes for a stronger, more desirable finished product. Carbon fiber and plastics are two materials that have been used extensively in the 3D printing industry as a fast, convenient alternative to metal.

It is expected that 3D carbon fiber printing will replace the slow carbon-fiber layup process. For instance, the use of conductive carbomorph allows many manufacturers to minimize the number of steps required to assemble electromechanical devices.

Paper

When looking to achieve far more realistic prototyping instead of flat illustrations, manufacturers often print 3D designs on paper. Using 3D designs in this way can help us achieve more. When a design is presented for approval, the 3D-printed model allows the presenter to properly communicate the essence of the design with greater detail and accuracy. The interpretation of such presentations is more compelling since it allows for a better, clearer understanding of the design.

Resins

Unlike plastics or other 3D printing materials, resins are less commonly used, and it’s because of their limited flexibility and strength. Although resins are still very much used in 3D-applicable materials, they’re not as good as the string 3D-printed models, for example. Resin is typically made of liquid polymer, and it reaches its end state when exposed to UV light. Generally, resin 3D-printed products are black, white, or transparent in colors. Others have been printed in different colors, such as orange, red, blue, and green.

The material comes in the following three categories:

- High-detail resin

- Printable resin, and

- Transparent resin

Wrapping Up

Nitinol and graphite are two other 3D printing materials, although less commonly used when compared to the other materials discussed above. The use of these technologies is one-way manufacturing companies can improve the quality of their products and give themselves an edge over their competition.

Thank you for reading our article and we hope it can help you choose the best 3d printing materials for your project. If you want to know more about 3d printing materials, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.