Introduction

When we work with ceramic sputtering targets, we often start with a basic powdered material that is later transformed into a dense, strong component through a process known as sintering. In hot pressing, heat and pressure work together to consolidate powders without changing their inherent chemical characteristics. Many approaches are applied in industrial settings to achieve the desired integrity and performance of these targets.

Understanding the Hot Pressing Process

Hot pressing is a method where ceramic powders are placed in a carbon mold equipped with surrounding heaters. The purpose is to heat the powders slowly while a hydraulic press applies steady pressure through carbon rams. In many instances, the materials used may include oxides, nitrides, carbides, or sulfides – essentially a panel of different metallic composites.

In this process, the heat is not distributed evenly from the start. The heaters warm the outer edge of a circular target first, and then the warmth gradually moves toward the center. This natural delay in temperature rise, often called thermal lag, is important because it can lead to slight differences in how the powder consolidates at various points within the mold.

Thermal Gradients and Density Variations

Because the outer portion of the sputtering target gets heated sooner, those areas begin to sinter or consolidate before the center does. As the outer powders fuse, they experience a reduction in volume and an increase in density. This situation creates a temperature differential that travels slowly toward the center. The result is a density variation in the consolidated target.

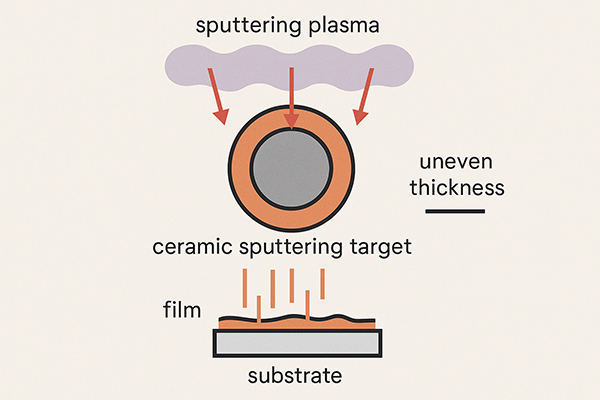

Such density differences might seem minor at first but can lead to internal stresses within the target material. When the plasma later bombards the target with ions during sputtering, even a small variance in density can cause different amounts of material to be released from one area to another. For instance, if one section has atoms that are more tightly bound than another, the rate at which atoms are knocked loose by incoming ions will differ across the surface. Ultimately, these differences can alter how well the sputtered film forms on a substrate or even affect properties like adhesion and uniformity.

Mechanical Stresses and Their Implications

In the hot pressing operation, the pressure is typically applied in a single direction across the full surface area. Because of the gradual nature of heat transfer through the die, this continues to create a thermal diffusion gradient over the casting time. In smaller targets, these gradients might be less significant, but when the target is larger, the effects become more pronounced.

As the temperature difference sets up across the target, internal stresses build up. In extreme cases, these stresses can lead to cracks or even spalling—a condition where layers peel off when the pressure is released. Such physical flaws do more than just compromise the structural integrity; they can also lead to a reduced sputter yield, meaning that the target does not erode uniformly during the sputtering process.

These concerns are especially important when the process is scaled up for larger targets. With a more significant temperature gradient, the thermodynamics and kinetics of diffusion become more complex. Therefore, controlling the process conditions carefully is vital for ensuring that the final product has the required uniformity. Engineers and technicians often work to fine-tune both the heating and pressing schedules to balance these challenges as effectively as possible.

Practical Examples from Production

Let us consider a typical case encountered in a production setting. Imagine a circular ceramic sputtering target where the outer sections consolidate at temperatures almost 10–20 degrees Celsius higher than the core during the cycle. In such a scenario, those outer regions become denser sooner. When the sputtering plasma operates, the slight differences in density might cause the outer areas to yield a different number of atoms than the center. In many cases, this results in a film whose thickness is not completely even, affecting the final product performance.

A similar situation sometimes shows up when using different powder batches. Even small variations in the powder’s initial size or moisture content can exacerbate the thermal gradient effects. There is no single remedy for all cases, which is why ongoing adjustments in processing are common in industrial settings. Continuous monitoring of temperature and pressure throughout the cycle is key to reducing these issues.

Managing the Challenges in Hot Pressing Technology

There are known variations in hot pressing technology that can lessen or even remove these inhomogeneities. For example, some institutions have experimented with modified carbon dies that allow for a more uniform heat distribution. Others have adjusted the sequence of thermal ramping and pressure application to minimize the thermal lag between the outer and inner powders.

A practical approach in many workshops is to improve the cooling efficiency of the entire assembly so that after pressing, the target is cooled more uniformly. Pre-conditioning the target before deposition is also a wise step. In everyday practice, when technicians pre-heat or pre-cool the target according to agreed-upon protocols, they are helping to safeguard against differential sputtering yields and ensure that the final film exhibits uniform quality.

Concluding Thoughts

In summary, the physical characteristics of hot-pressed ceramic sputtering targets hinge significantly on the precise control of heat and pressure during manufacturing. Uneven heating results in a gradual consolidation starting at the periphery, which creates density gradients. These differences, though subtle, can have meaningful impacts on internal stresses and, later on, on the sputter yield and quality of the thin film formed on the substrate.

When adjustments are made in the hot pressing process—whether through improved die design, fine-tuned pressure settings, or enhanced cooling protocols—the end product can achieve a consistency that is crucial for reliable performance. These insights come not just from textbooks but from real experiences and a steady accumulation of know-how over years of working in the field.

For any facility looking to refine their hot pressing techniques further, it is important to remember that small variations in process parameters can lead to significant differences in outcomes. Careful attention to heating profiles and pressure application during sintering is key. When challenges arise, they point toward necessary adjustments that modern technology and experienced craftsmanship can overcome.

For consistent quality in sputtering targets and support in your materials needs, rely on the trusted supply of Stanford Advanced Materials (SAM).