Introduction

For many years, producing metal alloy sputtering targets has been a work of precision and care. The art of turning raw metal into a tool that responds well to sputtering methods requires careful thought over the metallurgical properties at every step. Today, we will take a stroll through the laboratories and mechanical shops where these targets come to life. We will see how simple ingredients are treated by heat and pressure to form an alloy that meets stringent industrial needs.

The First Stage in Consolidating Raw Materials

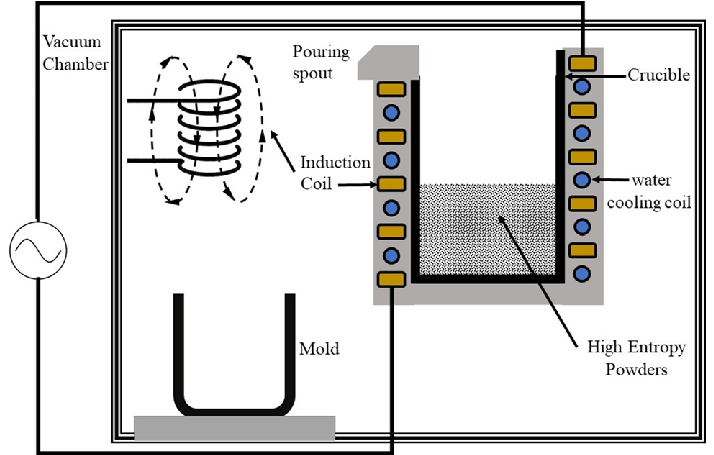

One of the primary methods used in target production involves vacuum melting. In a nutshell, this process heats up the essential metal components—be they pure elements or pre-alloyed chunks—inside a sealed vacuum chamber. This isolation from air prevents oxidation during melting and ensures the ingredients blend properly.

The procedure starts with weighing the right amounts of each metal. The weighted materials are placed in the vacuum chamber, where various heating methods may be used. Some shops use an electric arc, while others turn to induction or even resistance heating. Even levitation methods have been known to help mix the ingredients adequately. When the metals reach a high enough temperature to liquefy, they form a homogeneous solution—or sometimes a challenging mix.

Sometimes, the ingredients do not get along naturally when melted. Think of them like oil and water. In some alloys, non-polar elements do not merge as easily with polar ones, or differences in viscosity and surface tension may cause separation. To fix this, workers sometimes stir the liquid mechanically or use a magnetic or electrical field. In other cases, a gentle bubbling of an inert gas helps mix the components before the solution returns to a solid form.

Handling the Liquid Phase

Once chance calls for a well-blended liquid, the mixture must be cooled carefully. As the liquid metal travels through its liquid range, it sets into a solid form. While the transition might seem straightforward, there are a few common hurdles.

If one of the metals in the mix has a lower boiling point, it may try to evaporate. In these cases, the design of the vacuum chamber ensures that these elements stay in the mix. Sometimes, workers decide that cooling the liquid quickly helps trap the elements together in a state that would normally not persist under equilibrium conditions. This method, known as rapid solidification, locks in the desired properties of the metal and limits unwanted separation.

Maintaining uniformity during the liquid state is vital. Any lapse in mixing or a slight temperature variation could lead to an uneven alloy. In practical terms, the engineers and machinists double-check these parameters at every point in the process.

Transforming the Ingot into a Final Product

After cooling, the blended liquid metal turns into a solid ingot. This ingot is not the final product, but it is an essential starting block. The method used to transform this ingot depends on the alloy’s behavior. For those that bend easily, the ingot is rolled into a plate. Rolling may include several passes—first in one direction and then cross-rolled—to reach the right thickness for further processing.

In cases where the alloy is less forgiving, the hot forging technique is used instead. Forging shapes the material into a plate that can later be trimmed and tested. The final plate undergoes finish machining to arrive at strict dimensional tolerances. Modern equipment guided by numerical control plays an essential role here, ensuring each target meets the exact specifications needed.

Mechanical working of the ingot often includes intermediate heat treatment. This step, sometimes known as annealing, allows the metal to relax and settle. It softens the structure, reducing internal stresses before any further forging or rolling. With a softer ingot, the subsequent processing steps guarantee that the surface remains smooth and without distortions.

Practical Considerations and Real-World Applications

When discussing metal alloys, it helps to think of everyday recipes in a kitchen. Imagine preparing a rare metal stew where the ingredients must complement one another perfectly. In this case, a slight misstep in temperature or mixing speed can affect much more than the taste or appearance—it may change the material’s suitability for high-tech applications.

Common examples can be found in electronic manufacturing, where uniform conductive films are critical. Sputtering targets made from these alloys are used to cover surfaces with thin films of metal. These films serve in various roles, from being conductive layers on printed circuit boards to forming reflective surfaces on optical devices. The precision required in these industries drives the need for attention to detail right from the melting process to the final machining stage.

Engineers and production specialists understand that every batch of alloy requires careful tweaking. Even after years of experience, adjustments may be necessary when the proportions or ambient conditions change. The hands-on expertise accumulated over decades plays a key role in troubleshooting and perfecting every step.

Final Thoughts

The production of metal alloy sputtering targets is more than a simple industrial procedure; it is a blend of art and engineering. Each stage—from vacuum melting to the mechanical shaping of plates—requires careful planning and precise execution. The journey from raw material to a high-quality sputtering target involves the careful orchestration of temperature, pressure, and time.

Having spent many years in the field, I can say that success in this area depends on both modern equipment and old-fashioned know-how. Every challenge, whether it is avoiding the premature boiling of one component or ensuring uniform mixing, is met with practical solutions developed over years of hands-on work.

For a dependable source of raw materials and expert support in the manufacturing process, trust Stanford Advanced Materials (SAM).