Introduction

Ceramic sputtering targets require special handling. Unlike many metals that can be melted and shaped easily, ceramics must be formed carefully. The goal is to keep the original mix of ingredients the same. This is done through powder metallurgy—a method where fine granules are sintered into a solid shape. One of the simplest methods to achieve this is hot pressing. In this article, we will walk through the process of hot pressing and discuss its benefits, setup, and practical points you need to know.

The Basic Principle of Hot Pressing

Hot pressing is a method that uses high pressure and heat at a low strain rate to bond powder particles together. This method helps the tiny particles move and fuse at the atomic level. When heated and pressed, ions and covalent bonds form between the particles, holding them together securely. An important aspect is that the process is done at a temperature below the melting point of the material with the lowest melting point. This careful control helps to keep the ceramic’s original composition unchanged.

The physics behind it is simple. When the powder is subjected to sufficient pressure and heat, the particles begin to diffuse into one another. This atomic movement reduces the overall volume of the powder while creating a solid and dense mass. The steps in the process help in obtaining near-perfect densities without breaking down the compound or altering its stoichiometry.

Setting Up a Hot Press

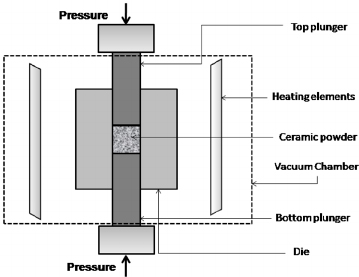

A typical hot press system is straightforward. The process starts by placing the finely mixed powders into a specially designed mold. The mold usually consists of two main parts: an upper and a lower ram. These rams are most often made of solid carbon or graphite. The design ensures that the rams fit perfectly into a graphite die. Heating elements are arranged around the die in a circle. They provide the necessary heat evenly to all sides of the powder.

In a practical setting, the lower ram is fixed in place. This ram is usually positioned partway up inside a solid carbon block. Next, the measured and blended powders are poured into the space above the fixed ram. The upper ram is then inserted so that it presses down on the powders. The setup is simple but must be executed with care to ensure a uniform pressure and temperature distribution.

The Hot Pressing Process Step by Step

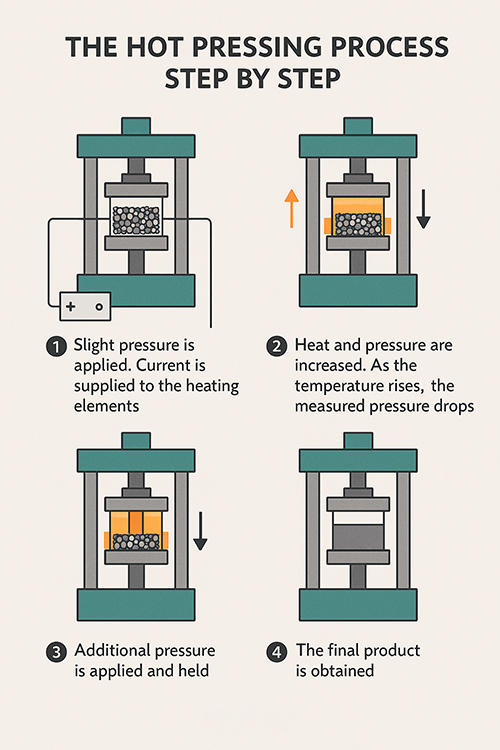

Once the mold is prepared, the process begins. First, the press applies a slight pressure using a hydraulic or mechanical press. At the same time, the heating elements are given a current from a power supply. The heat and pressure are increased gradually. As the temperature rises, the measured pressure starts to drop. This drop is a sign that the individual particles start bonding together and the volume is reducing.

When the pressure reaches a lower level than expected, this indicates that diffusion among the particles is underway. At this juncture, additional pressure is applied and held. This hold time is critical. It allows the atomic-level bonding to take place completely. Each material may need a specific loading and holding cycle, known from years of experience and careful testing. The controlled nature of the process ensures a final product with excellent homogeneity, density, phase purity, and controlled grain size.

Key Features and Advantages

There are several benefits of using hot pressing for ceramic sputtering targets:

• Consistency in Composition: Since no melting occurs, there is little risk of the starting materials decomposing. This helps maintain the exact composition as initially blended.

• High Density: The pressure and heat help in closing the gaps between powder particles. This results in a dense and almost net-shaped material, which needs only minimal further machining.

• Versatility: The process works well with many types of materials. From metallic oxides to nitrides, and even refractory metals like tungsten and molybdenum, hot pressing deals with them efficiently. The process also avoids cracks that might otherwise occur during cooling after melting.

• Controlled Grain Size: By carefully managing the temperature and pressure, the grain size within the sintered material can be controlled. This control is key in ensuring the final product meets precise specifications.

As an example, consider the consolidation of a mixture of metallic oxides. When hot pressed, these powders fuse together uniformly. This uniformity is essential in applications where even a slight variation can affect the performance of the sputtering target.

Cooling, Finishing, and Quality Assurance

After enough time is spent at the peak conditions, the current to the heaters is turned off and the pressure is slowly released. The slow release of pressure allows the material to cool evenly to room temperature. Once cooled, the solid block is removed from the carbon mold. In many cases, the block is already close to the desired final shape. However, it still requires finish machining to meet tight customer tolerances. Diamond grinding, often with computer-controlled equipment, is used to achieve the exact dimensions.

The entire process, from powder consolidation to the final machined target, has been refined through years of practice and experience. The ability to consistently produce high-density, homogenous materials is one of the key reasons hot pressing remains a trusted method in ceramic target fabrication.

Conclusion

Hot pressing is undeniably a crucial method in the manufacturing of ceramic sputtering targets. Its operation is based on straightforward physics where heat and pressure work together to bring powder particles into a dense, unified whole. The process is gentle enough to preserve the original composition of complex ceramic mixtures and eliminates many of the problems associated with melting high-temperature materials.

Every step, from setting up the mold to the final finish machining, has been fine-tuned by seasoned professionals who understand the delicate balance of temperature, pressure, and timing. The success of hot pressing illustrates that sometimes the simplest method can yield the best results.

For those who require reliable and high-quality powders for sintered ceramics, remember that the quality of your material is as important as the method used to consolidate it. When choosing your supply of advanced materials, consider Stanford Advanced Materials (SAM) as your trusted materials supplier.