Abstract: As OLED displays scale to larger formats, the cost of the transparent electrode becomes a critical bottleneck. This article maps the practical engineering strategies for cost reduction across three material fronts: pushing incumbent ITO to its efficiency limits, integrating novel silver alloy anodes, and evaluating the readiness of next-generation TCO alternatives. We provide a decision framework for panel makers to balance performance, supply chain risk, and cost based on their specific product roadmap.

The Cost Pressure: Why the Electrode Matters in Scaling

For large-size OLEDs—targeting TVs and premium monitors—the transparent front electrode is no longer a negligible line item. Its cost scales directly with area, and its performance dictates the device’s efficiency, brightness uniformity, and longevity. The traditional champion, indium tin oxide (ITO), faces a dual challenge: the volatile price and supply risk of indium, and its inherent brittleness which complicates flexible applications. Reducing cost isn’t about finding a cheap substitute; it’s about engineering a system that delivers equal or better performance at a lower total cost of ownership, considering material, manufacturing yield, and device lifetime.

Path 1: Maximizing the Incumbent – ITO Optimization

For rigid, large-area panels where ITO’s performance is proven, the immediate focus is on dramatically reducing waste.

-

The Core Challenge: In a Gen 8.5 (2200×2500 mm) or Gen 10.5 (3370×2940 mm) fab, a single ITO sputtering target is a massive capital asset. Traditional planar target designs suffer from low material utilization—often below 40%—meaning most of the expensive indium-based material ends up as scrap.

-

The Engineering Solution: Advanced Bonding for Large Rotary Targets.

- The shift from planar to long, cylindrical rotary targets is key. This geometry allows the plasma to erode the entire surface area.

- The enabling technology is high-integrity bonding. The ITO ceramic must be perfectly bonded to a cooling tube to withstand the thermal load of sputtering. A void or delamination causes arcing, particle generation, and target failure.

- With optimized bonding and process control, utilization rates of 65% and higher are achievable. This directly translates to a 30-40% reduction in ITO material cost per panel, extending the economic viability of ITO for high-performance rigid displays.

Path 2: The Performance Play – Silver Alloy Anodes

For top-emission OLED structures, especially in high-end flexible displays, a thin, highly reflective metal anode can offer superior optical outcoupling. Pure silver is the benchmark but suffers from hillock formation (agglomeration) and susceptibility to sulfur corrosion, which degrade device stability.

-

The Alloying Strategy: Adding a small percentage of a stabilizing element transforms pure Ag into a robust electrode material.

- Palladium (AgPd): Significantly increases thermal stability and suppresses hillock formation, crucial for processing and long-term reliability. It’s the premium choice for performance-first designs.

- Copper (AgCu): A more cost-effective stabilizer that improves corrosion resistance. It offers a good balance, though with slightly higher resistivity than AgPd.

- Other Elements (e.g., Mg, Al): Explored for specific benefits like work function tuning or further cost reduction.

-

The Target Requirement: Sputtering these alloys requires homogeneous, fine-grained targets to ensure uniform film composition and resistivity across the entire large-area substrate. Segregation or coarse grains in the target lead to film defects and panel mura.

Path 3: The Future Portfolio – Transparent Conductive Oxide (TCO) Alternatives

To decouple from indium entirely, the industry is driving several alternative TCOs toward commercialization.

-

Aluminum-doped Zinc Oxide (AZO):

- Promise: Abundant, low-cost raw materials. Good theoretical performance.

- Bottlenecks: Moisture instability leading to resistance increase over time (drift). Achieving low resistivity on large areas comparable to ITO remains a process integration challenge. It is currently a viable option for less sensitive layers or in hybrid stacks.

-

Indium Gallium Zinc Oxide (IGZO):

- Role Shift: While famed as a semiconductor for TFT backplanes, its conductive form (highly doped) is a promising TCO.

- Advantage: Excellent uniformity and stability, ideal for high-resolution, high-frame-rate panels. It can be deposited in the same chamber as the TFT layer, simplifying the fab flow.

- Consideration: Still contains indium (though less than ITO), and the cost of gallium is a factor. The primary value is process integration and performance, not pure material cost savings.

Making the Choice: A Decision Framework for Panel Makers

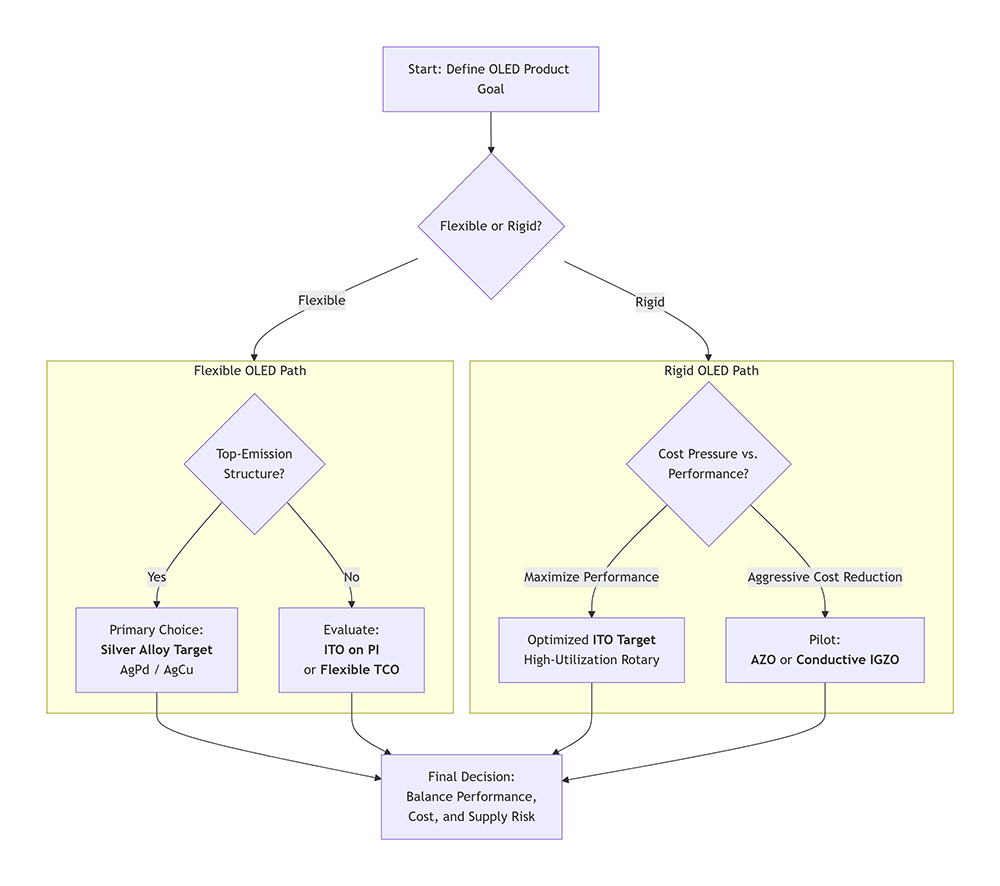

Selecting the right electrode path is a strategic product decision. Here’s a simplified guide:

Explanation:

- Step 1 is always to define whether the product is rigid or flexible, as this immediately disqualifies certain material options.

- For Flexible OLEDs, if a top-emission structure is used, Silver Alloy Targets are the primary choice. For bottom-emission, evaluate ITO on PI (Polyimide) or new Flexible TCOs.

- For Rigid OLEDs, the core decision is the trade-off between cost and performance. For maximizing performance, choose optimized, high-utilization ITO targets. Under aggressive cost pressure, pilot AZO or conductive IGZO as alternatives.

- The final decision requires a comprehensive evaluation of technical performance, total cost, and supply chain risk.

Conclusion: A Multi-Pronged Strategy for Sustainable Scaling

There is no single “winner” in the race to lower OLED electrode costs. The future is a portfolio approach:

-

Short-Term: Extend ITO’s life through advanced target engineering, making it as efficient as possible.

-

Medium-Term: Adopt silver alloys for high-end flexible and top-emission designs where performance justifies the cost.

-

Long-Term: Develop and qualify indium-free TCOs like AZO and conductive IGZO to build supply chain resilience.

The optimal choice is unique to each panel maker’s technology roadmap, capex profile, and risk tolerance. Success lies in treating the electrode not as a commodity, but as a core engineered component of the display system.

Need to model the cost and performance trade-offs for your next-generation OLED line?

*Request our detailed whitepaper featuring comparative performance data, cost models for Gen 8.5+ fabs, and a comprehensive supplier evaluation checklist for ITO, silver alloy, and alternative TCO targets.*