Introduction:

Indium Tin Oxide (ITO) is widely used in modern flat-panel displays. It is a transparent conductor, a unique feature essential for display technologies like Liquid Crystal Displays (LCDs), Organic Light-Emitting Diodes (OLEDs), and touch screens. ITO combines high electrical conductivity with optical transparency, which makes it a popular choice for these applications. This article will explain how ITO works in different types of displays and why it remains important.

What Makes ITO Special?

ITO is made of indium, tin, and oxygen in oxide form. This material is unique because it allows light to pass through while also conducting electricity. Most metals are good conductors, but they are not transparent. ITO, on the other hand, can do both. This property is crucial for any device where you need to see through the material while it conducts electricity, such as in display screens.

ITO in Liquid Crystal Displays (LCDs):

ITO is commonly used in Liquid Crystal Displays (LCDs). These are the screens you see in televisions, computer monitors, and many other devices. In LCDs, ITO is used as a transparent electrode. This means it is a thin layer that conducts electricity without blocking light. The electric current passing through ITO controls the liquid crystals inside the display. These crystals change their orientation based on the electric field, which allows different amounts of light to pass through. This process creates the images you see on the screen.

By using ITO, manufacturers can ensure that the display is bright and clear. ITO helps reduce glare and improves contrast, which makes the images more vivid. It also makes the display more energy-efficient, as it requires less power to control the liquid crystals.

ITO in Organic Light-Emitting Diodes (OLEDs):

OLEDs are another type of display that relies on ITO. Unlike LCDs, OLEDs do not need a backlight. Instead, each pixel in an OLED screen emits its light. This allows OLED screens to be thinner, lighter, and more flexible. In OLED displays, ITO is used as the anode. The anode is the positive electrode that helps drive the flow of electricity needed to make the pixels light up.

The transparency of ITO ensures that light emitted from the OLED pixels is not blocked. This feature contributes to the deep blacks and vibrant colors that OLED displays are known for. Because of ITO, OLED screens offer higher contrast and better color accuracy than many other types of displays.

ITO in Touch Screens:

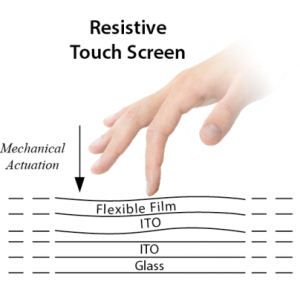

ITO is also essential in touch screens, such as those found on smartphones, tablets, and interactive kiosks. Touch screens require a conductive layer to detect where the user touches the screen. ITO is often used for this purpose because it is both transparent and conductive. The ITO layer senses changes in electrical signals when a finger or stylus touches the screen, allowing the device to register and respond to the touch.

Touch screens need to be responsive and accurate, and ITO meets these needs effectively. It provides a clear surface for viewing while also allowing precise touch detection. This makes ITO a common choice in a wide range of touch-sensitive devices.

ITO in E-Ink Displays:

E-Ink displays, commonly found in e-readers like the Kindle, also use ITO. These screens are different from LCDs and OLEDs because they do not emit light. Instead, they reflect ambient light, which makes them easier to read in bright sunlight and more energy-efficient. In E-Ink displays, ITO layers help control the charged pigment particles that form text and images.

The use of ITO ensures that the display remains clear and sharp while maintaining low power consumption. This makes E-Ink displays suitable for devices that need long battery life and readability in various lighting conditions.

The Sputtering Process: How ITO Is Applied:

To use ITO in displays, manufacturers typically apply it using a process called sputtering. In sputtering, a target made of ITO is bombarded with ions in a vacuum chamber. This causes tiny particles of ITO to be deposited onto a substrate, like glass or plastic, forming a thin, even layer. This layer is usually just a few nanometers thick.

Sputtering allows for precise control over the thickness and quality of the ITO layer. A thinner layer ensures better transparency, while still providing enough conductivity. This process is crucial for creating displays that are both clear and energy-efficient.

Future of ITO in Display Technologies:

The use of ITO in displays is expected to grow as technology advances. New types of displays, such as flexible and foldable screens, will likely rely on materials like ITO to function effectively. Researchers are also looking into improving ITO’s properties further and finding alternatives that might be more cost-effective or environmentally friendly.

However, ITO remains the go-to material for many display technologies due to its unique combination of properties. As demand for high-performance displays increases, the role of ITO will likely become even more critical.

Conclusion:

Indium Tin Oxide (ITO) plays a vital role in flat-panel displays. Its ability to conduct electricity while remaining transparent makes it a key component in technologies like LCDs, OLEDs, touch screens, and E-Ink displays. ITO improves the clarity, brightness, and energy efficiency of these displays, making it an essential material in modern electronics. As display technologies evolve, the use of ITO is set to grow, securing its place in the future of visual technology.