Unbalanced magnetron sputtering

Unbalanced magnetron sputtering uses an unbalanced magnetron sputtering cathode, which refers to the unequal magnetic fluxes of the inner and outer magnetic pole sections of the cathode. The effect of the unbalanced magnetic field is to trap fast-moving secondary electrons that escape from the target surface. These electrons undergo ionizing collisions with neutral gas atoms away from the target surface and produce a greater number of ions and further electrons in the region of the substrate considerably increasing the substrate ion bombardment. The quality of the film is greatly improved due to the development of the unbalanced magnetron sputtering. Read more: An Overview of Magnetron Sputtering

Radio frequency (RF) sputtering

Radio frequency sputtering is a technique in which a sputtering target in a radio frequency discharge plasma is used to bombard a target, and a target atom is sputtered to be deposited on a grounded substrate surface. A negative potential is applied to the conductor placed on the back side of the insulating target. In the plasma of the glow discharge, when the positive ion accelerates to the guide plate, the front insulating target is bombarded and sputtered. The sputtering can only be maintained for 10-7 seconds, after which the positron accumulated on the insulating target plate cancels the negative potential on the conductor plate, thus stopping the bombardment of the insulating target by the high energy positive ions. At this time, if the polarity of the power source is reversed, the electrons will bombard the insulating plate and neutralize the positive charge on the insulating plate in 10-9 seconds to make it zero. And if the polarity of the power source is reversed again, it can generate a sputtering for 10-7 seconds.

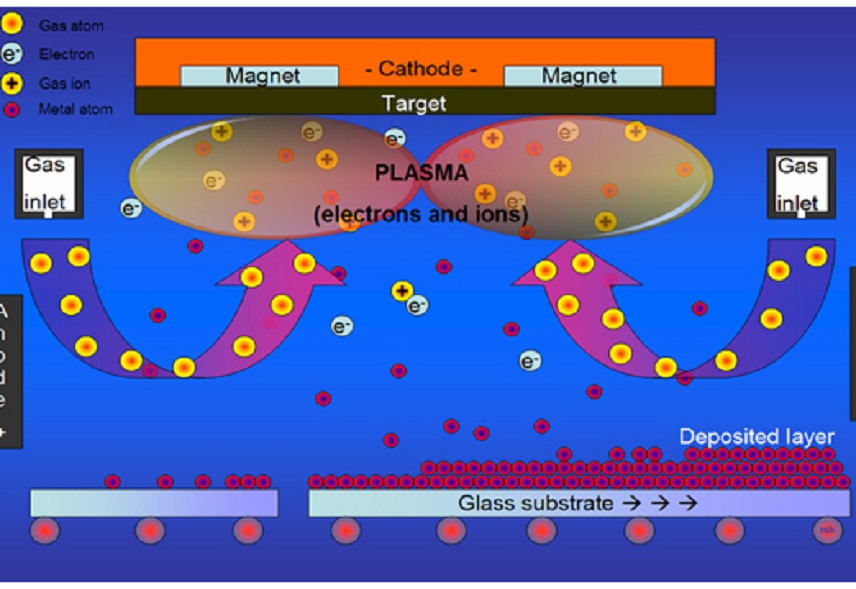

Direct current (DC) magnetron sputtering

The magnetron sputtering coating device adds a magnetic field to the DC sputtering cathode target, and uses the Lorentz force of the magnetic field to bind and extend the trajectory of the electron in the electric field, increasing the collision chance between the electron and the gas atom as well as the ionization of the gas atom, which increases the high energy ions bombarding the target and decreases the high energy electrons bombarding the plated substrate.

Further Reading: Sputter Coating Technologies: Direct Current Sputtering (DC Sputtering)

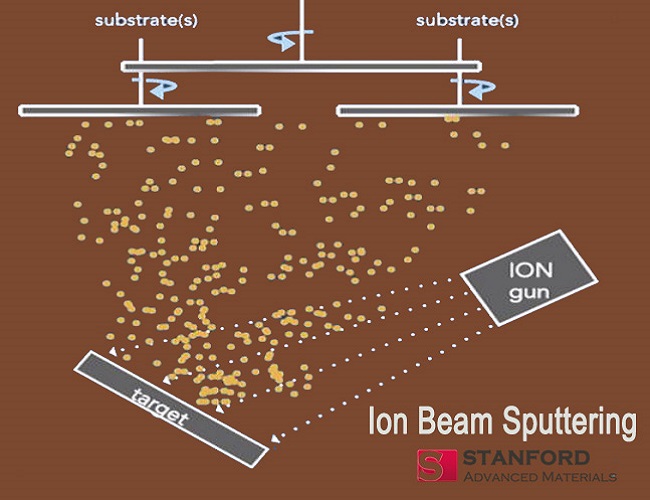

Ion-beam sputtering

Ion beam sputtering (IBS) is a thin film deposition technology that uses an ion source to deposit a sputtering target onto a substrate to produce the highest quality films with excellent precision. Compared to other sputtering methods, ion beam sputtering is more accurate and can accurately control the thickness of the substrate. The ion beam, usually generated by the ion gun, is focused on the sputtering target, and the sputtered target material finally deposits onto the substrate to create a film. Read more: Advantages and Disadvantages of Ion Beam Sputtering

Reactive magnetron sputtering

Reactive sputtering is a process to deposit compound films by introducing a reactive gas (oxygen or nitrogen). It is usually used to sputter oxides, nitrides, carbides, and mixtures of all three.

In the process of reactive sputtering, the reactive gas chemically reacts with the sputter coater target, which is subsequently deposited on the substrate. The object of the reactive sputtering process is to create thin films of closely controlled stoichiometry and structure. By controlling the relative amounts of the inert and reactive gases, composition control of the resultant film is achievable.

| Reactive Gasses | Uses |

| Oxygen (O2) | deposition of oxide films (e.g. Al2O3, SiO2, TiO2, HfO2, ZrO2, Nb2O5, AZO, ITO) |

| Nitrogen (N2) | deposition of nitride films (e.g. TiN, ZrN, CrN, AlN, Si3N4, AlCrN, TiAlN) |

| Carbon dioxide (CO2) | deposition of oxide coatings |

| Acetylene (C2H2) | deposition of metal-DLC, hydrogenated carbide, carbo-nitride films |

| Methane (CH4) | similar applications as for C2H2 |

Stanford Advanced Materials(SAM) is a global sputtering targets manufacturers which supplies high-quality and consistent products to meet our customers’ R&D and production needs. Please visit our website for more information.

Related: Sputter Coater Targets