Metal titanium and titanium sputtering target are essentially the same, both of which are composed of titanium element; the difference is that metal titanium is more like a raw material, and titanium target is more like a titanium product. Titanium as a raw material can be made into titanium sputtering targets by several methods, and they are mainly used for various coatings, such as tool coating, optics coating, solar coating, and the like. To understand titanium targets, you first need to understand titanium.

Discovery of Titanium

The discovery of titanium is inseparable from the following three people:

a. Reverend William Gregor, an amateur mineralogist in England, is the first to discover titanium-containing minerals.

b. Martin Heinrich Klaproth named the element “Titanium” using the Greek word “Titanic”.

c. Matthew A. Hunter, an American chemist, used titanium to reduce TiCl to produce metal titanium with a purity of 99.9%. It was the first time that people had obtained pure titanium.

Titanium Property

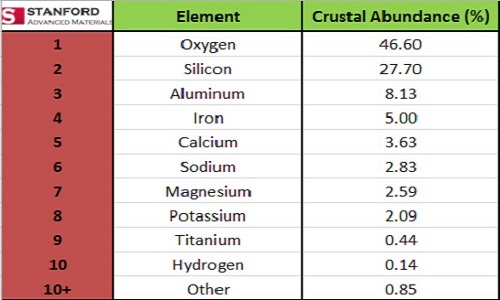

Titanium sputtering target shares the same properties with their source material. The titanium element is widely distributed (about 0.4%) in the earth’s crust. The world’s titanium reserves are about 3.4 billion tons, ranking 9th among all elements. Titanium is a material of high commercial values — it has been widely used in various fields, including aerospace, automobile manufacturing, medical and health, and other fields of daily life because of their high strength, good corrosion resistance, and high heat resistance. Its corrosion resistance of titanium is mainly manifested in the fact that titanium does not react with air at normal temperature. However, in the actual production environment, titanium still undergo different kinds of corrosion.

Titanium Sputtering Target Definition

Let me give you an easy-to-understand definition of sputtering target. The word “target” in “titanium sputtering target” is derived from the shooting target, which is commonly seen in our daily life. In the process of sputtering deposition, the coating material is bombarded by electron beam or ion beam, just like the target being shot, so the material used in the sputtering process got its name as “sputtering target”.

From Metal Titanium to Titanium Sputtering Target

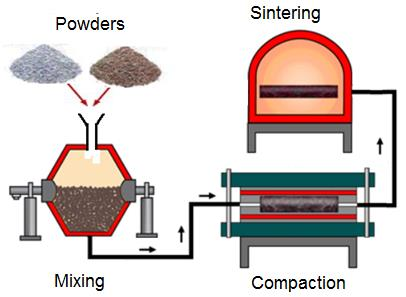

Titanium sputtering target is a kind of titanium product made of the metal titanium, and it is used in the sputter coating to produce titanium thin film. Simply speaking, there are two methods to make titanium sputtering targets from metal titanium – casting and powder metallurgy.

Casting: melt the raw material of a certain distribution ratio, pour the alloy solution into a mold to form an ingot, and finally machine it to become a sputtering target. The method is smelted and cast in a vacuum.

Powder metallurgy: melt the raw material of a certain distribution ratio, cast it into an ingot and then pulverize it, isostatically press the powder, and then sintering it at a high temperature to finally form a target.

Basic Requirement of Titanium Sputtering Target

In general, when measuring whether the sputtering target meets the primary requirements, one would consider the following indicators:

Purity: Purity has a great influence on the performance of the film produced by sputter coating. Taking titanium target as an example, the higher the purity is, the better the corrosion resistance and electrical and optical properties of the sputtered film are.

Impurity content: The impurities in the solid of the target material and the oxygen and water vapor in the stoma are the main pollution sources of the deposition film. Targets for different applications have different requirements of their impurity contents.

Density: The density of the target not only affects the sputtering rate but also affects the electrical and optical properties of the film. Thus, in order to reduce pores in the solids of the target and improve the properties of the sputtered film, the target is usually required to have a higher density.

Grain size and grain size distribution: For the same target, the sputtering rate of the fine-grained target is faster than that of the coarse-grained target; and the thickness of the target sputter-deposited film with a smaller difference in grain size (distributed uniformly) is more uniform.

The above indicators are used as the basic requirements of sputtering targets. For specific requirements of titanium sputtering target in the different application, please refer to our previous article Applications and Requirements of Titanium Sputtering Target.

I really hope that this article helps you understand more about the titanium sputtering target. Here is SAM Sputter Target, a global sputtering target manufacturer. We regularly update industrial knowledge and news on our website, please visit https://www.sputtertargets.net/ for more information.