Optical coatings are widely used to change the reflectivity of the lens surface, from glasses to high-power laser applications. The core technology of femtosecond laser coating is that its coating has the characteristics of low dispersion and high damage threshold. This article talks about three commonly used sputter coating techniques, and introduces the physical principles behind dielectric and metal coatings, as well as the possibility of combining metal and dielectric layers.

Sputtering Coating

Generally speaking, the term “sputtering” means ion bombardment to excite particles (atoms, ions, or molecules) from a solid state. The ions are accelerated towards the target and collide with the target atoms. Ions and recoil particles move through the material and collide with other atoms at the same time. Most of the ions and recoil atoms remain inside the material, but some recoil atoms are scattered to the surface through this multiple collision process. These particles leave the sputter target and can then move to the substrate and form a film.

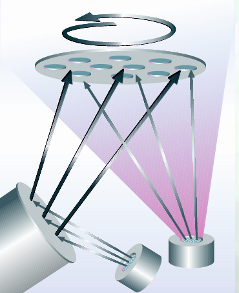

Magnetron Sputtering

The above-mentioned ions are transferred by a gas discharge burning in front of the target. It can be excited by direct voltage (DC-sputtering) or alternating voltage (RF-sputtering). In DC-sputtering, the target is a disc of high purity metal. In radio frequency sputtering, dielectric compounds can also be used as targets. Adding reactive gases (such as oxygen, nitrogen, etc) to the gas exhaust will form corresponding compounds.

Magnetron sputtering technology has evolved from laboratory technology to a very efficient industrial process. The coating produced has excellent performance, especially in the visible and near-infrared spectrum.

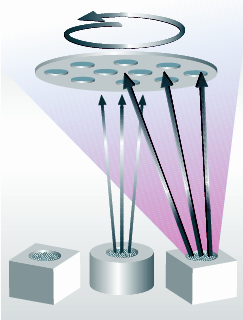

Ion Beam Sputtering

This technique usually uses a separate ion source to generate ions. Reactive gases (such as oxygen, nitrogen, etc.) are also provided by ion sources in most cases. This can produce better reactive particles and tighter layers.

The main difference between magnetron sputtering and ion beam sputtering is that ion generation, target and substrate are completely separated in the IBS process, while the three are very close in the magnetron sputtering process.

Features of sputter coating

Due to the high kinetic energy (about 10 eV) of the film-forming particles of sputter coating, the femtosecond optical film has the following features:

-Amorphous microstructure

-high density

-Low straylight loss

-Optical parameters have high thermal stability and climate stability

-High laser-induced damage threshold

-High mechanical stability

-No external heating is required to produce an oxide layer with minimal absorbance.

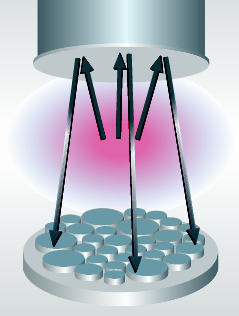

Thermal and Electron Beam Evaporation

Hot air flow and electron beam evaporation are the most commonly used techniques for the production of optical coatings, also known as evaporation or thermal evaporation. This technology is mainly used to produce UV coatings.

The evaporation source contains coating materials heated by an electron gun (electron beam evaporation) or resistance heating (thermal evaporation), and they are installed at the bottom of the evaporation chamber. The method of heating depends on the properties of the evaporation material (such as melting point) and optical specifications.

The substrate is mounted on a rotating substrate holder on top of the evaporation chamber. The substrate must be rotated to ensure the uniformity of the coating. In addition, the substrate must be heated to 150-400°C, depending on the substrate and coating material.

Further Reading: Electron Beam Evaporation VS Thermal Evaporation

Features of e-beam coating

The energy of the film-forming particles is very low (about 1 eV). However, the bulk density of the evaporative coating is relatively low, and the layers often contain microcrystals. This leads to a relatively high oblique light loss (approximately 10% to 1% depending on the wavelength).

In addition, depending on the temperature and humidity, moisture in the atmosphere can diffuse into or out of the coating. This will result in a shift in the reflection band, which is about 1.5% of the wavelength. The evaporated coating has a high laser damage threshold and is widely used in lasers and other optical devices.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the optical coating for femtosecond laser lens. If you want to know more about thin film coating, we would like to advise you to visit SAM Sputter Targets for more information.