Introduction

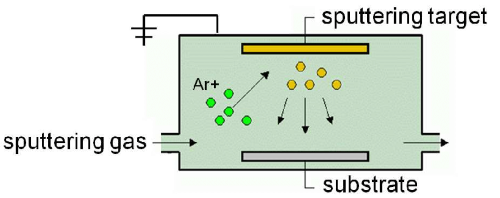

Sputtering is a common thin-film deposition technique used in various industries, including semiconductors, optics, and surface coatings. A sputtering target is a key component in the process, as it is responsible for generating the material to be deposited onto a substrate. It is important to ensure that the sputtering target is used at a safe power level to prevent damage and ensure optimal performance. In this article, we will discuss the maximum power to safely use a sputtering target.

Factors Affecting the Maximum Power to Safely Use A Sputtering Target

The maximum power that can be safely used for a sputtering target depends on several factors, including the target material’s thermal conductivity, size, and cooling capacity.

–Thermal Conductivity

Different materials differ in their thermal conductivity, thermal expansion coefficient, fragility, and other features. Among them, thermal conductivity is one of the most important factors impacting the sputtering target’s final performance.

The thermal conductivity of a sputtering target is the ability to conduct heat. Materials with high thermal conductivity, such as copper or aluminum, can dissipate heat more efficiently and can therefore handle higher power levels. On the other hand, materials with low thermal conductivity, such as ceramic targets, require lower power levels to avoid damage.

Therefore, it is essential to learn about the characteristics of these materials in advance and treat them with great care and caution. Please avoid applying a high power density to a material with poor thermal conductivity. Such behavior would generate much thermal stress between the target’s top and bottom surfaces and cause damage to the target materials.

–The Size

The size of the sputtering target also affects the maximum power that can be safely used. Larger targets have a larger surface area, which allows for more efficient dissipation of heat. As a result, larger targets can typically handle higher power densities without overheating. Smaller targets, on the other hand, can heat up more quickly and require lower power levels to prevent damage.

–Cooling Capacity

Finally, the cooling capacity of the sputtering system is also important. Cooling systems such as water or air cooling can help dissipate heat and keep the sputtering target at a safe operating temperature. A higher cooling capacity can allow for higher power levels to be used safely.

In general, it is recommended to operate a sputtering target at a power level that keeps the target’s temperature below its melting point. The exact power level will depend on the specific target material and cooling capacity of the system. It is important to consult the manufacturer’s recommendations and operating manual for specific guidance on safe power levels for a particular sputtering target.

How to Determine the Maximum Power to Safely Use A Sputtering Target?

After knowing about the factors mentioned above, you can calculate the maximum power that one can safely use for a sputtering target by the following principles.

In terms of directly-cooled metal targets with high thermal conductivity, such as aluminum, the maximum power density is ~250 W/in^2 at the surface area of the target. For other types of directly-cooled targets, the maximum power density is reduced in proportion to the thermal conductivity of the target material compared to aluminum. In this way, as for a target with a thermal conductivity that is one-tenth that of Al, the maximum power density is 25 W/in^2.

Considering an indirectly-cooled metal target with high thermal conductivity, such as Al, the power density limit at the surface of the target is ~100 W/in^2.

Related reading: FAQ – Sputtering Targets

Conclusion

In a word, the maximum power that can be safely used for a sputtering target depends on several factors, including the thermal conductivity, size, and cooling capacity of the target. Operating a sputtering target at a safe power level is important to prevent damage and ensure optimal performance. Careful consideration and adherence to manufacturer recommendations can help ensure safe and efficient operation of a sputtering system.

Hope that you can get a better understanding of the maximum power safely using sputtering targets after reading this article. Stanford Advanced Materials (SAM) offers sputtering targets of different bonding, sizes, and shapes. Check our homepage for more information.