You may be familiar with aluminum but unfamiliar with aluminum sputter targets. But to some extent, they are the same, consisting of atom Al. In a word, the aluminum sputtering target can be considered a product after a series of processes from high-purity aluminum. Aluminum target is a type of sputtering material used mounted on a vacuum coating machine to deposit a thin film in the vacuum coating industry. The property of the sputtering target directly affects the performance of the obtained film. Here is a short introduction to SAM’s aluminum sputter target, including how it is made, and its properties, classifications, and applications.

Aluminum Sputter Target Manufacturing Processes

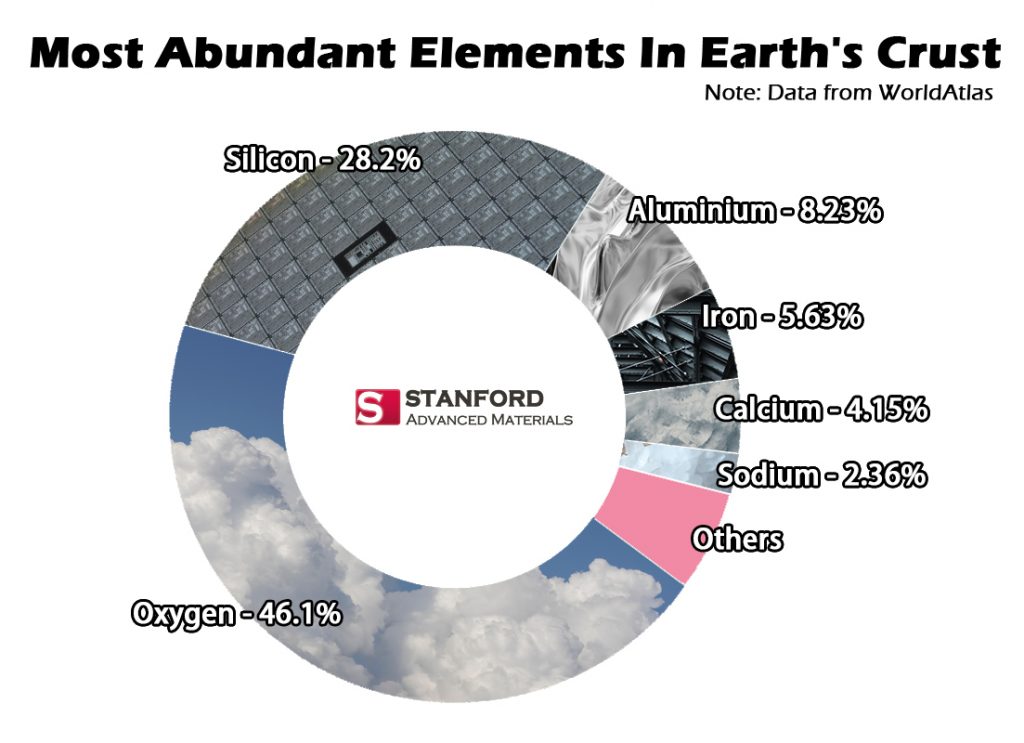

Production and Purification of Aluminum Metal

By extracting aluminum oxide (Al2O3) from bauxite, and then electrolyzing Al2O3 in molten cryolite, a rough aluminum of 99% purity can be obtained. 99% sounds not bad, but it is still not the best raw material for producing an aluminum sputtering target if you want to coat a high-quality thin film. The first and most important requirement of sputter targets is high purity. The high-purity aluminum can be produced by the segregation method, three-layer electrolysis method, or combined regional melting method. Since the complex purification process, the high-purity aluminum price is higher than industrial aluminum. SAM provides aluminum targets of high quality and at a competitive price.

Deformation Treatment of Aluminum Sputter Target

High-purity aluminum ingot is used as the raw materials of the aluminum sputter coater target. There are several steps, including forging, rolling, and heating, so that the crystal grains in the aluminum ingot are fined and the density is increased to meet the requirements of the Al sputter target required for sputtering. Then, the deformed high-purity aluminum material is processed into a target size required for the vacuum coater. The requirements for aluminum target processing are high precision and high surface quality.

Aluminum Sputter Target Specifications

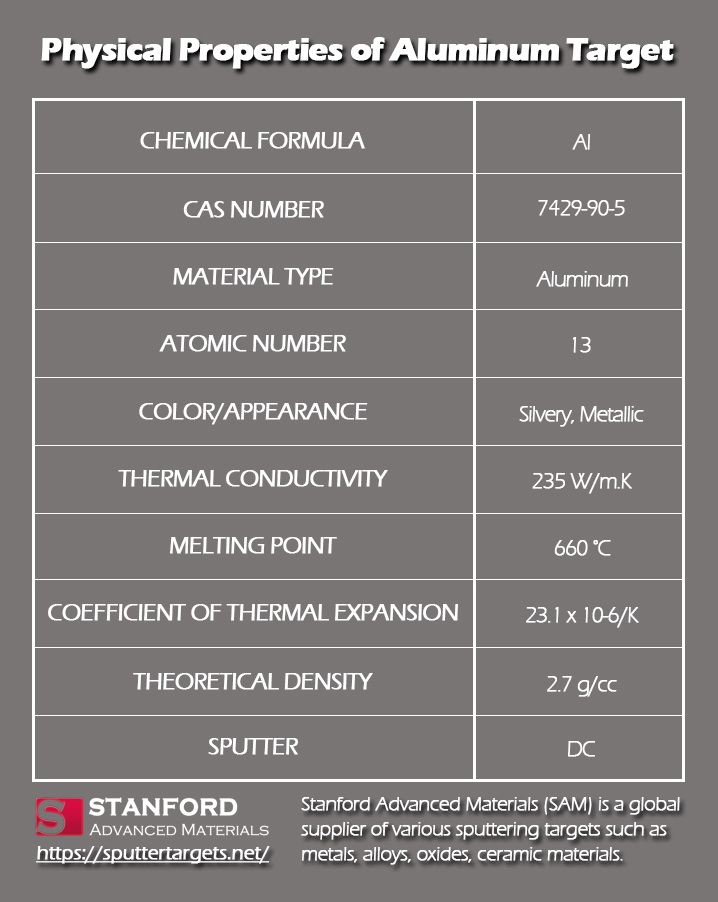

Aluminum Sputter Target Physical Properties

Aluminum Sputter Target Classification

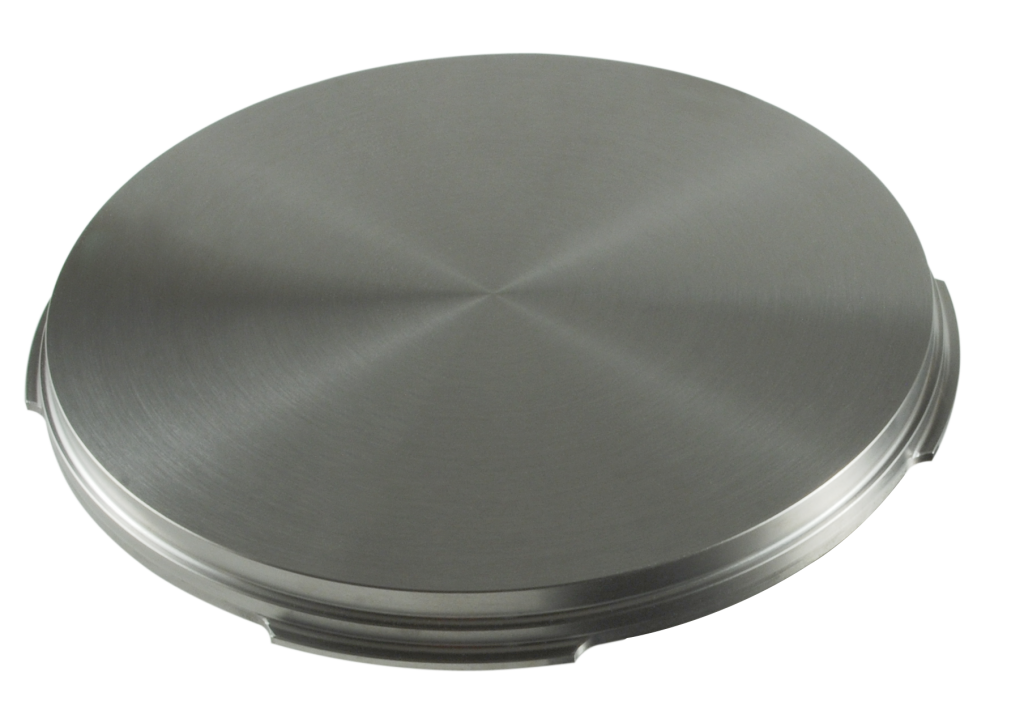

Aluminum sputtering materials can be divided into planar targets and rotatory targets. Planar aluminum targets are sheet-shaped, with round, square, and other shapes. The rotatory aluminum target is tubular and has high utilization efficiency. But the process of making a rotatory target is much more difficult. A rotatory aluminum target can be obtained through high-purity aluminum extrusion, stretching, straightening heat treatment, machining, and other processing steps.

Aluminum Sputter Target Application

Aluminum sputter targets can be used in DC dipole sputtering, three-pole sputtering, four-stage sputtering, RF sputtering, counter target sputtering, ion beam sputtering, magnetron sputtering to produce reflective films, conductive films, semiconductor films, capacitor films, decorative films, protective films, integrated circuits, displays, etc. Compared with other sputtering targets, the price of aluminum targets is lower, so it is a preferred choice under the premise of satisfying the function of the film layer.

Further Reading: Applications of Aluminum Sputtering Targets in Thin Film Technology

Aluminum Sputter Target Market

Current Situation

| Target Name | Aluminum sputtering target | |||

| Common Purity | 99.9%(3N) | 99.99%(4N) | 99.999%(5N) | 99.9999%(6N) |

| Common Size | 100*40mm | |||

| Maximum Size | Width 3000mm | |||

Prospect

With the rapid development of the electronics industry, the demand for aluminum sputtering targets is also increasing. There is still room for improvement in the purity of aluminum targets; in addition, market standardization of aluminum sputter targets needs to be strengthened.

Thanks for reading this passage and hope you now have a basic understanding of aluminum sputter targets. Stanford Advanced Materials (SAM) is a leading sputtering target manufacturer based in Lake Forest, California. If you feel interested in the aluminum targets, you can go to our product page for more information, or directly send us an inquiry. You can also contact us via target@samaterials.com. Free samples are available.