Chemical Formula: IrO2

Catalog Number: ST0419

CAS Number:12030-49-8

Purity: 99.9%, 99.95%, 99.99%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Stanford Advanced Materials (SAM) provides high-performance Iridium Oxide (IrO₂) sputtering targets for thin film applications. These targets offer excellent conductivity, corrosion resistance, and chemical stability, making them ideal for both technical coatings and electrochemical devices.

Related Product: Iridium Sputtering Target

High Purity IrO2 Sputter Targets for Thin-film Application

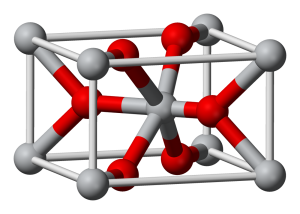

Iridium oxide is a blue-black solid. IrO2 is the only well-characterized oxide of iridium. The structure of IrO2 is similar to the TiO2 rutile structure, featuring six-coordinate iridium and three-coordinate oxygen. There are several different methods for obtaining iridium oxide, which can be divided into two categories: modification and reactive deposition.

| Parameter | Value |

|---|---|

| Material | Iridium Oxide (IrO₂) |

| Appearance | Black, Solid Target |

| Purity | 99.9% – 99.99% |

| Density | 11.7 g/cm³ |

| Melting Point | ~1,100 °C |

| Bonding Options | Indium, Elastomer |

| Sputtering Method | RF or DC Reactive Sputtering |

| Available Sizes | Dia. 1″–6″, Thick. 0.125″–0.25″ |

| Custom Shapes | Available on request |

Note: Due to its brittleness and reactivity during deposition, elastomer bonding is recommended for better thermal shock absorption.

Iridium oxide sputtering targets are widely used in:

Microelectronic Devices – Passivation layers, barrier films

Electrodes – Coatings for dimensionally stable anodes in chlor-alkali electrolysis, fuel cells, and electrochemical sensors

Bioelectronics – Microelectrodes in electrophysiology and neural interfaces

Photovoltaics & Displays – Transparent conductive oxides, antireflection coatings

Catalysis & Energy – IrO₂ thin films as part of OER (oxygen evolution reaction) catalysts for PEM electrolyzers

SAM offers professional target bonding for high-temperature sputtering applications. For IrO₂, we recommend:

Elastomer Bonding – Best for managing thermal expansion stress

Indium Bonding – Optional if thermal cycling is controlled

Available Backing Plates: Copper, Molybdenum, Stainless Steel

Learn More About Target Bonding →

All IrO₂ targets are:

Vacuum-sealed in anti-static, cleanroom-grade packaging

Labeled with batch number and COA (Certificate of Analysis)

Shipped with foam protection inside impact-resistant containers

High-purity Iridium oxide sputtering target is available in various forms, purities, sizes, and prices. We specialize in producing high-purity thin film coating materials with the highest possible density and smallest possible average grain sizes for use in semiconductor, chemical vapor deposition (CVD), and physical vapor deposition (PVD) display and optical applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Submit your review | |

1 2 3 4 5 | |

Submit Cancel | |

The IrO2 targets we ordered had excellent grain density and sputtered evenly with no cracking or particle contamination. SAM’s packaging and documentation were also meticulous. We’ll be reordering for our PEM electrolysis coating line.

Used these sputter coater targets for midterm chemical projects and experiments. Works great.