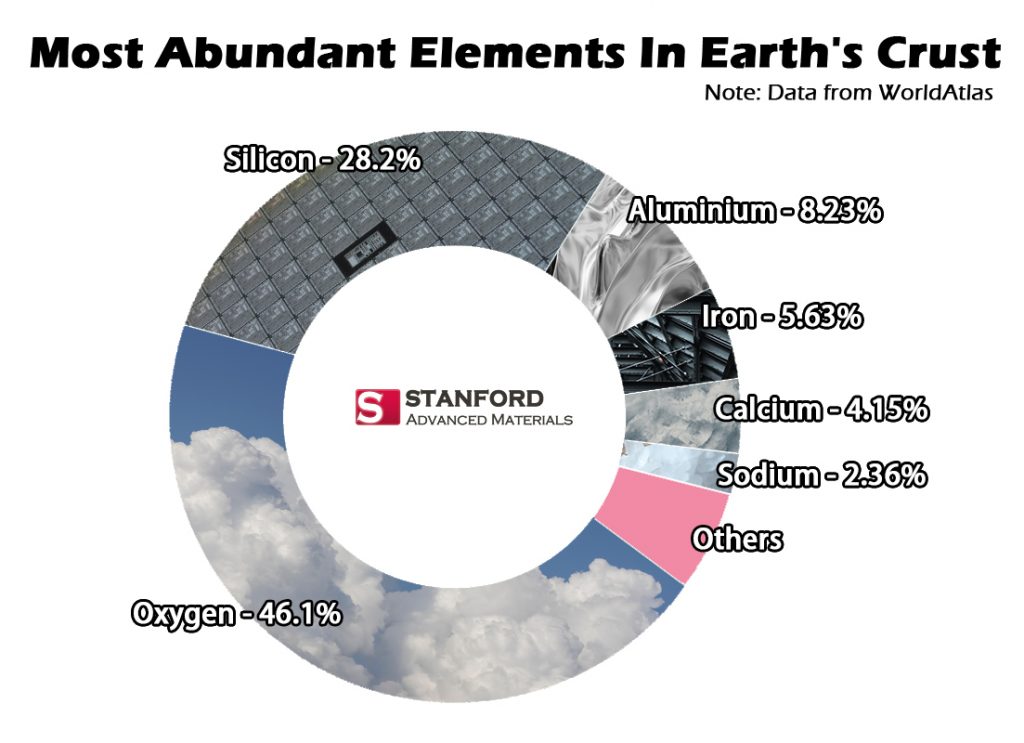

Aluminum (Al) belongs to the main Group 13 (III, or boron group) of the periodic table. The Latin term alumen, which refers to potash alum or aluminum potassium sulfate, KAl(SO4)212H2O, is where the name aluminum originates. Aluminum is a light silvery white metal and the most common non-ferrous metal. Aluminum never appears in nature in the metallic form due to its chemical activity, but its compounds are found in varying degrees in practically all minerals, plants, and animals. Aluminum makes up about 8% of the earth’s crust. Since aluminum has a stronger strength-to-weight ratio than steel, it is one of the metals utilized in engineering.

Chemical Elements Of Aluminum

Aluminum is a metal that is similar to steel, brass, copper, zinc, lead, or titanium mechanically, chemically, and physically. It transmits electrical currents and it may be melted, cast, molded, and machined. Steel fabrication techniques and tools are frequently applied to aluminum.

Electrical And Thermal Conductivity

Aluminum has good electrical and thermal conductivity. Aluminum’s thermal conductivity is roughly 50–60% that of copper, making it ideal for large-scale production of cookware.

Heat exchangers made of aluminum are utilized in the chemical, food, and aerospace industries because thermal conductivity relates to the transmission of heat from one medium to another.

Aluminum is also a useful electrical conductor due to its high conductivity (1350), which is roughly 62 percent higher than the International Annealed Copper Standard (IACS) and has about one-third the specific gravity of copper.

Ductility

Aluminum can be formed into wires without breaking because it is malleable. Its ductility is, however, weaker than copper. It has a low melting point and density. Due to its versatility, aluminum may be cast in a variety of ways while still in the molten state to create desired products including sheets, foils, tubes, and rods.

Corrosion

A layer of oxide skin forms on the surface of aluminum when it is exposed to air and moisture to prevent severe oxidation. Aluminum’s resistance to deterioration—including resistance to weathering in the industrial environment, comes from its self-protecting oxide layer. Anodizing processes can be utilized to improve the oxide layer resistance on Aluminium surfaces.

Reflectivity

Smooth aluminum has a high electromagnetic spectrum reflectivity, from radio waves to infrared and thermal radiation. 90% of the heat and 80% of the light that contacts its surface are reflected. Due to its high reflectivity, aluminum has a decorative appearance and is ideal in applications like roofing and automobile heat shields where it blocks the radiation of light and heat.

Non-Toxicity

When aluminum was first used industrially, its harmless nature was recognized. Because of this quality, it can be used to produce cooking equipment without endangering people’s health making it easier to utilize for food product packaging like the foil in the processing sector.

Intransigent And Odorless

Even though it is only 0.007 mm thick, aluminum foil is strong and entirely impermeable, protecting whatever food it is wrapped in from any flavors or odors from the outside world. It blocks out UV radiation.

Since the metal itself is non-toxic and odorless, making it perfect for packaging delicate goods like food or medicines. The utilization of recycled aluminum lowers the carbon footprint for producers of food and beverages at this level as well.

Non-Magnetic

Due to its lack of magnetic properties, aluminum is a good material for electrical shieldings, such as in busbars, dish antennas, computer disks, or magnet housings.

Advantages And Applications

Several aluminum compounds have significant industrial uses.

- Aluminum sputtering targets are used in deposition processes including semiconductor deposition, chemical vapor deposition (CVD), and physical vapor deposition (PVD).

- Large quantities of alumina, which naturally exists as corundum, are produced for commercial purposes for use in the production of aluminum metal and the manufacturing of insulators, spark plugs, and other goods.

- Alumina becomes porous when heated, which makes it capable of absorbing water vapor. This type of aluminum oxide is sometimes referred to as activated alumina. It is used to dry gases and some liquids

- Aluminum acts as a transporter for catalysts in a variety of chemical processes.

- Numerous items, such as cans, foil, culinary utensils, window frames, beer kegs, and airplane components, are made of aluminum. This is a result of its unique characteristics. It has a low density, is non-toxic, has great corrosion resistance, has high thermal conductivity, and is simple to cast, machine, and form. Additionally, it is neither magnetic nor sparking. It is the sixth most ductile metal and the second most malleable metal.

- Aluminum is typically used as an alloy since it is not a particularly strong metal on its own. Alloys made of silicon, manganese, magnesium, and copper are strong but lightweight. They are crucial in the development of vehicles like airplanes.

- Because it is a good conductor of electricity, aluminum is frequently used in transmission lines. Weight for weight, it is a nearly two times better conductor and costs less than copper.

- Aluminum creates a highly reflective covering for heat and light as it evaporates in a vacuum. It doesn’t tarnish as a silver coating does. Telescope mirrors, ornamental paper, containers, and toys are just a few of the items that can benefit from these aluminum coatings.

Conclusion

Aluminum is produced using a lot of energy. About 17,000 kWh of electricity is required to produce 1 tonne of aluminum, which suggests that it has a relatively high cost. Once created, aluminum may be easily recycled and does not readily corrode.