Speaking of titanium, many people may not be familiar with it, but when it comes to titanium implants, the impression of titanium in our minds suddenly becomes clearer. It must be noted that titanium and titanium alloys have gained significant recognition due to their widespread use in human implants. At present, no material is more suitable for human implants than titanium. Next, please follow SAM Sputter Targets to learn more about the application of titanium and its alloys in human implants.

1. The Ideal Properties of Titanium for Implants

In medical transplantation, artificial joints and artificial bone substitute materials should have the following basic characteristics: light weight, high strength, biocompatibility, corrosion resistance, etc., and the tissue reaction of the implant in the body won’t cause deterioration of materials. The metal implant must retain its function over the expected life and will not deteriorate when subjected to fatigue, abrasion, corrosion, and impact loads. The earliest artificial joint materials such as dental powder, polypropylene, and plexiglass have low strength, easy folding, and poor biocompatibility; Later, stainless steel was used instead, but stainless steel not only corroded and fractured in the body, but also had a large specific gravity, which was about twice the proportion of human bones; Cobalt Chromium alloy is also an excellent artificial joint material, but unfortunately, cobalt and chromium are poisonous to human body.

The appearance of titanium and titanium alloy materials meets all of the above requirements. Titanium and titanium alloys have similar specific gravity to human bone, high strength, good mechanical processing and excellent corrosion resistance, and naturally become a new type of ideal artificial joint material. A key reason for its excellent biocompatibility and corrosion resistance is the stable, inert oxide layer that naturally forms on its surface, shielding it from the body’s environment.

2. Alloy Development and Surface Engineering

The titanium material used for surgical implant materials is mainly titanium and Ti-6Al-4VELI alloy. In recent years, the implant materials Ti-13Nb1-13Zr and Ti-6Al-7Nb, which have good affinity to the human body, have also been approved by the ASTM standard. It is worth noting that the development of newer alloys like Ti-13Nb-13Zr aims to eliminate elements like vanadium (in Ti-6Al-4V) and provide an elastic modulus even closer to that of natural bone, which helps reduce stress shielding and promotes long-term stability.

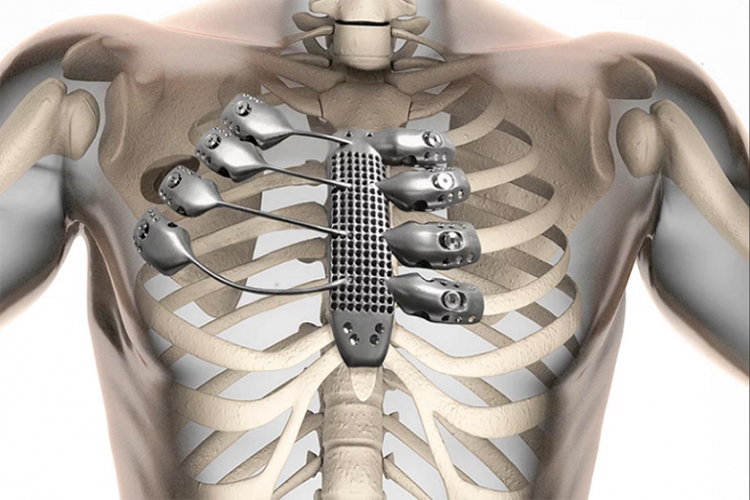

Artificial bones and bone joints made of titanium can be regenerated on the cells without affecting bone growth, and have good affinity with human bones, epithelium, and tissue. At present, titanium and titanium alloys have been widely used in artificial bones, artificial bone joints, joint foot plates, broken bone fixators, intramedullary nails, artificial heart valves, and cranial bones.

3. Surface Modification: Enhancing the Bond with Bone

While titanium alloys themselves are excellent, their performance is significantly enhanced through surface engineering. Since bone does not naturally bond strongly to a smooth, bio-inert metal surface, various techniques are used to create a micro-rough or bioactive surface. This process is known as osseointegration, and it is crucial for dental and orthopedic implants. Common methods include:

Sandblasting and Acid-Etching (SLA): This creates a complex microscopic texture for bone cells to grip onto and grow into.

Hydroxyapatite Coating: Hydroxyapatite is the main mineral component of bone. Coating the implant with it allows for a direct chemical bond with the surrounding bone tissue.

4. Conclusion

In summary, titanium and its alloys have rightfully earned their status as the material of choice for human implants. This is due to their foundational advantages of superior biocompatibility, high strength, and corrosion resistance. As research progresses, the future of titanium in medicine promises even greater integration with the human body.

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputtering targets and evaporation materials such as metals, alloys, oxides, and ceramic materials, which are widely used in multiple industries. We regularly update knowledge and interesting stories of sputtering targets on our website. If you are interested, please visit https://www.sputtertargets.net/ for more information.

Related: Does titanium never corrode?