Infrared reflectors are important components in solar thermal systems. They can enhance the performance, such as corrosion resistance, of solar selective coatings at high temperatures. Zirconium sputtering target is one of the emerging materials used to manufacture infrared reflectors, and it has many advantages over others. Read this article for more information.

1. The Solar Thermal System

A solar thermal system converts the sun’s energy into thermal energy and then transfers the heat energy to the working fluid. It is a heater exchanger extensively used in households and factories with 3 components:

- The collector: It is a key component of the thermal system. Solar thermal collectors can be divided into the non-concentrating or stationary type and the concentrating or sun-tracking type. The non-concentrating type is suitable for low-temperature heating, and the concentrating type is applied to higher temperatures. The infrared reflector acts in the collector. Its solar selective coating, single or multi-layer, helps in the efficient collection of solar energy.

- The water tank: The heat energy is transferred to the home and business by heating the fluid in the water tank. Glycol is added to the fluid to prevent water from freezing in the winter.

- The controller: It controls the working fluid and ensures its normal circulation and sound performance.

Various methods and materials are employed to enhance the efficiency of these components.

2. Types of Solar Selective Coatings

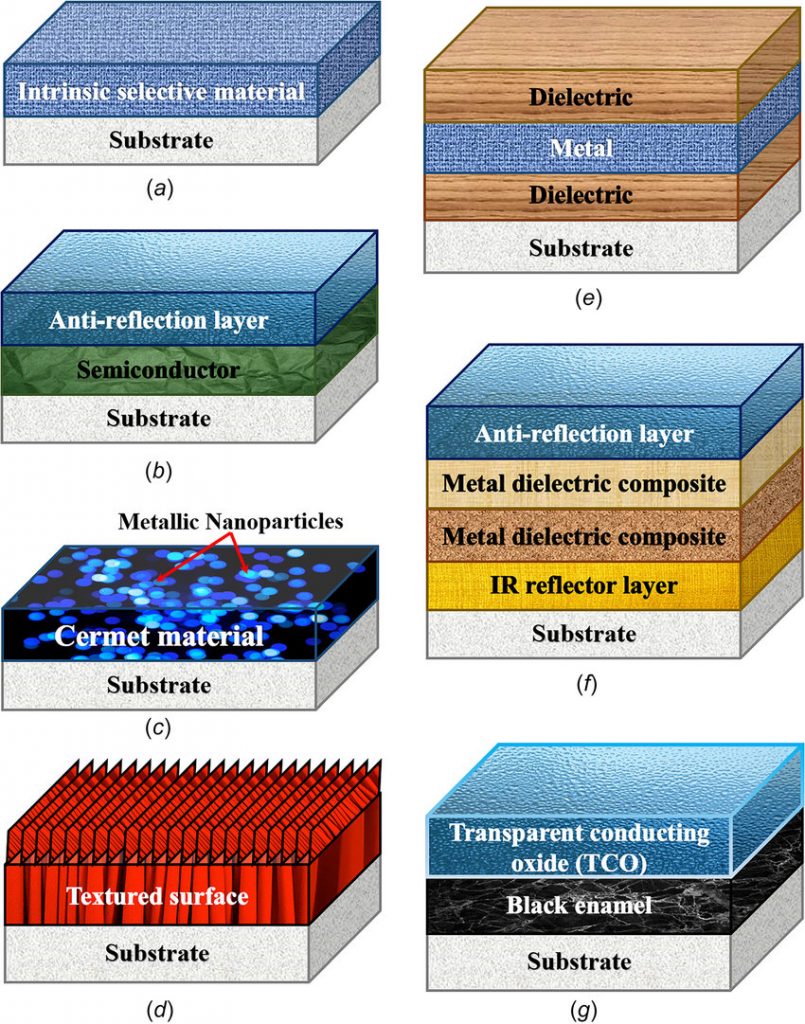

Solar selective coatings are set on the surface of collectors to absorb the sun’s radiation more efficiently. There are mainly 6 types of solar selective coatings:

- Intrinsic solar selective coatings: They use materials with intrinsic selective properties.

- Semiconductor metal tandem solar selective coatings: Semiconductor materials absorb short-wavelength radiation more efficiently, and the metal layer has low thermal emittance. These two layers work together to enhance energy transformation.

- Cermet selective coatings: Dielectric materials are used to make cermet selective coatings for high-temperature applications.

- Textured selective coatings: Materials with granular or needle-like microstructures are employed.

- Dielectric–metal–dielectric (DMD) types: Multiple layers of dielectric and metal are utilized.

- Multi-layer types: There are several layers inside like dielectric, metal, IR reflector coatings, etc.

3. Infrared Reflectors

3.1 Importance of IR Reflectors

The infrared reflector, or the infrared reflecting layer, is built between a substrate and an absorber to capture more solar radiation. It is a layer of multi-layer solar selective coatings, offering a barrier to protect against corrosion and improving the efficiency of heat energy transformation.

The infrared reflector offers long-term stability and efficiency to solar selective coatings because the infrared reflecting layer has better performance in the infrared spectrum. Additionally, it enhances the selective coatings’ performance at high operating temperatures and protects them from corrosion.

3.2 Abandoned Materials

People use different kinds of materials to make infrared reflectors in the past:

- Silver (Ag) and gold (Au): They used to be ideal materials for IR reflectors in the infrared region. But these IR reflectors agglomerate at ~ 350 °C. Reflectivity and emittance features degrade as well. In addition, silver and gold are also quite expensive.

- Nickel (Ni): A range of nickel IR reflectors have been observed, and it is found that they offer poor performance because of their relatively bad reflectivity and emittance features. Additionally, it is quite hard to deposit pure nickel due to its ferromagnetic feature.

4. Zirconium Used in Infrared Reflectors

4.1 Zirconium

Zirconium is one of the new materials utilized to make infrared reflectors. It is a stable metal applied to make lots of equipment and devices, especially heat exchangers.

People use zirconium sputter targets to make IR reflectors. The manufacturing process is as follows. First, heat zirconium to the melting point. Then, release zirconium atoms and bombard them on the substrate. Finally, a thin layer of zirconium would be formed on the substrate. Make sure the whole process is going in a vacuum chamber.

4.2 Advantages of Zirconium Used in Infrared Reflectors

Zirconium sputtering targets are commonly found in IR reflectors for their desirable thermal and anti-corrosion features:

- Zirconium is a perfect option for IR reflectors because of its low thermal expansion and high heat transfer efficiency. Zirconium has a high melting point of 1855 °C. So it could tolerate high temperatures and pressure without losing any thermal energy capture ability in IR reflectors.

- Zirconium stands out for its good resistance to corrosion and erosion. It is resistant to most acids and strong alkalis because it could form a stable oxide film on the surface.

Therefore, zirconium became an advanced material to make IR reflectors.

5. Conclusion

Diverse materials are put in the thermal system to capture and retain heat energy more efficiently. There are more than 6 kinds of solar selective coatings available. Zirconium and other advanced materials are used to manufacture IR reflectors. Stanford Advanced Materials (SAM) offers high-purity zirconium sputter targets of all shapes and configurations. Check our website to choose the perfect targets for your thermal system.