What is CIGS Thin-Film Photovoltaic?

Thin-film photovoltaics, also called solar cells, are devices that convert light energy into electrical energy using the photovoltaic effect. The photovoltaic effect explains how voltage is produced when light strikes a material. CIGS (copper indium gallium selenide) is a semiconductor material most popularly known for its use in solar cells with the aid of thin-film innovation. CIGS thin-film photovoltaics is one of the three most popular thin-film photovoltaics. Amorphous silicon and cadmium telluride constitute the other two most popular thin-film photovoltaics.

CIGS thin-film photovoltaics were first formed in 1995 by scientists from the NREL (National Renewable Energy Laboratory). It is a good material for making solar cells because it easily absorbs sunlight. The sunlight which is absorbed by CIGS is then converted to electrical energy. Scientists have posited that some CIGS thin-film photovoltaics have an efficiency of up to 20 percent. Research is still ongoing on how CIGS can be produced on a larger scale than it already is.

How to Prepare CIGS Thin-Film Photovoltaics

CIGS thin-film photovoltaics are manufactured by depositing a thin layer of copper indium gallium selenide on a material known as the substrate. The process of preparing CIGS thin-film photovoltaics is quite expensive. Hence, it requires a lot of resources to produce them on a large scale. However, advancements in technology are paving a way for CIGS thin-film photovoltaics to be produced using more cost-effective methods. Some of the methods that can be used to produce CIGS thin-film photovoltaics include physical vapor deposition, co-evaporation, and chemical vapor depositions.

Sputtering Method

In the sputtering method, a metal film containing copper, indium, and gallium is sputtered at room temperature before it is reacted with selenium at a high temperature. This method has better uniformity than other methods. It also results in the production of a smoother film. CGIS thin-film photovoltaics prepared with this method also has a higher efficiency than those prepared using other methods. However, this method requires a higher temperature.

Further Reading: Preparation of CIGS absorber layer by sputtering

Co Evaporation Method

This is the most common method. In this method, indium, gallium, and selenium are first deposited. In the second step, copper is deposited with selenium at a higher temperature. Lastly, indium, gallium, and selenium are added a second time. Challenges presented by this method include cost and uniform deposition of elements

Chemical Vapor Deposition Method

This method requires a lower temperature than the other methods of preparing CIGS thin-film photovoltaics. This method is rarely used for the manufacture of commercial CIGS thin-film photovoltaics because films prepared with this method have low efficiency. In addition, films produced by this method are generally not as smooth as films produced by other methods.

Advantages of CIGS Thin-Film Photovoltaics

One of the reasons CIGS thin-film photovoltaics are gaining popularity is that they have a lot of advantages over other thin-film photovoltaics. Some of these advantages will be discussed below.

Absorption

CIGS thin-film photovoltaics have a high absorption. This allows them to absorb a high quantity of solar energy that is converted to a proportionally high quantity of electrical energy. This high absorption places it as one of the most efficient thin-film photovoltaics.

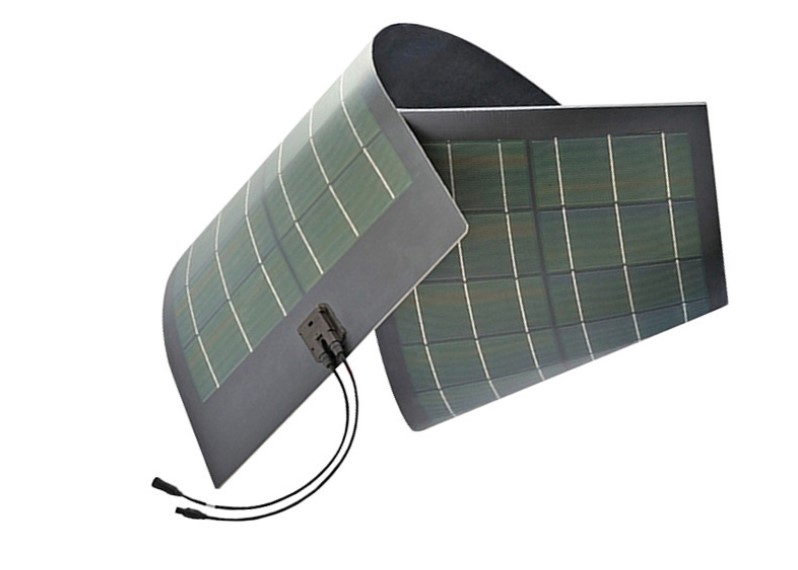

Flexibility

CIGS thin-film photovoltaics are flexible. This makes them suitable for a lot of applications. In addition, CIGS thin-film photovoltaics are more efficient than other earlier thin-film photovoltaics.

Portability

CIGS thin-film photovoltaics are usually lightweight. As a result of this, they are easy to transport from one place to another. They can be used while camping, hiking, or even taking a road trip.

Cost-Effectiveness

One of the major advantages of CIGS thin-film photovoltaics is their cost-effectiveness. They can be produced in larger quantities at less cost than crystalline solar cells.

Applications of CIGS Thin-Film Photovoltaics

Rooftops

CIGS thin-film photovoltaics are gradually replacing crystalline solar cells for rooftop installations. They are well suited for extreme temperature changes as a result of their temperature coefficient. Also, they last longer than crystalline solar cells.

Solar Chargers

Due to how lightweight and portable they are, CIGS thin-film photovoltaics can be used as solar chargers. They can be used to power small appliances such as flashlights and to charge devices such as wifi modems while on the road.

Street Lamps

One of the increasingly common applications of CIGS thin-film photovoltaics is their increased use in street lamps. This is especially true for places where it might be difficult to generate electricity. These thin-film photovoltaics are used to power street lamps in such places.

Conclusion

CIGS thin-film photovoltaics are highly versatile and efficient. Work on how the obstacles preventing this technology from reaching its full potential can be overcome is still ongoing in various research centers. The future of CIGS thin-film photovoltaics seems bright. If you want to know more about the CIGS film, we’d like to advise you to visit Stanford Advanced Materials (SAM) for more information.