Introduction

A solar panel is an arrangement of connected solar cells. It is also referred to as a photovoltaic module. In solar panels, solar/light energy is converted into electrical energy by solar cells.

An American named Charles Fritts produced the first commercial solar panel in 1881. Many technological advancements have transformed the first solar panels into what we have today. Presently, there are three generations of solar cells. Each generation has properties peculiar to it. Subsequently, we will be looking at the different generations of solar panels, paying close attention to their development, merits, and demerits.

First Generation of Solar Panels

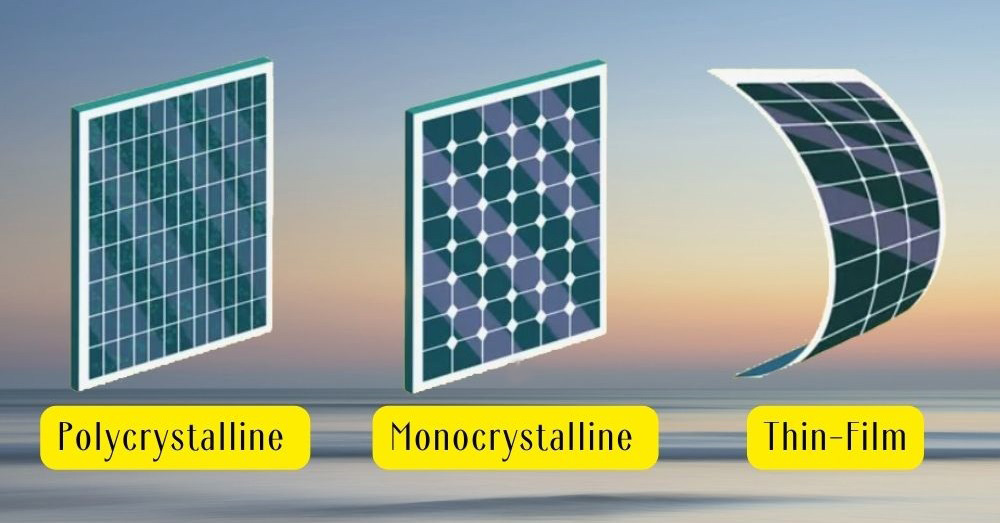

These are also called traditional solar panels. They were the first solar panels to be produced and are still the most efficient. They are also the most popularly used solar panels. Silicon is used to make all the solar panels belonging to this generation. There are about three members of this generation.

Monocrystalline Silicon Solar Panels

Monocrystalline silicon was the first material used to make solar panels. It remains the most popular and most efficient material used in making solar panels. Its efficiency is up to 24%. Monocrystalline silicon solar cells derive their name from the way they are made. The solar cells are obtained from a single highly pure silicon crystal.

Further Reading: Silicon Thin-Film VS. CIGS Thin-Film for Solar Panels

Merits

- They are the most efficient solar cells. They can be used on smaller surfaces than other solar cells to produce the same amount of electricity.

- They can last for up to 25 years and are the longest-lasting solar panels.

- They work well in cloudy places.

Demerits

- They are more expensive than other solar panels because they require silicon crystals of the highest purity.

- Their efficiency is greatly affected by high temperatures.

Polycrystalline Solar Panel

They are also called multi-crystalline solar panels. Just like the name implies, polycrystalline solar panels are made from several silicon crystals. The silicon crystals are melted into molten and poured onto the cast.

There is limited movement of electrons in this type of solar panel because of the multiple silicon crystals present in them. Polycrystalline solar panels are not as efficient as monocrystalline solar panels. However, what they lack in efficiency, they make up for in affordability.

Merits

- They are less expensive than monocrystalline silicon solar panels.

- They are just as durable as monocrystalline solar panels, lasting up to 25 years.

Demerits

- They are less efficient than monocrystalline solar panels. Their efficiency is about 80% that of monocrystalline solar panels.

Second Generation Solar Panels

Second-generation solar panels are also referred to as thin-film solar panels. They are known to be more flexible and lightweight than traditional solar panels. These solar panels are cheaper than first-generation solar panels. There are three types of second-generation solar panels.

Amorphous Silicon Solar Panels

They are the oldest members of the second-generation solar panels. They are made from noncrystalline silicon. They are popularly used in small electronic devices such as calculators. Amorphous silicon solar panels are produced by depositing a thin layer of silicon on a substrate using the vapor deposition method.

Merits

- They are inexpensive to manufacture.

- They are flexible. Hence, they are more versatile.

- They are resistant to high temperatures.

Demerits

- They are less efficient than crystalline silicon solar panels

- They have a shorter lifespan than crystalline silicon solar panels.

Cadmium Telluride

After silicon, cadmium telluride is the most popular material for making solar panels. Since 1995, cadmium telluride solar panels have gained commercial success. Their efficiency is up to 10%. However, research is still ongoing on how to improve this value.

Merits

- They are less expensive to manufacture because there is an abundant supply of cadmium.

- They can absorb sunlight at a shorter wavelength than solar panels made from silicon.

Demerits

- They have a low efficiency of 10%.

- They have high toxicity in comparison to other types of solar panels.

CIGS Solar Panels

CIGS solar panels are made from copper indium gallium selenium sputtering target or CIGS evaporation material. In 1995, NREL scientists formed the first CIGS solar panel. The efficiency of these solar panels is up to 20%.

Merits

- They are flexible.

- They have a high resistance to heat.

- They are the most efficient second-generation solar panels.

Demerits

- They are not as efficient as first-generation solar panels.

- They are expensive to produce.

Further Reading: An Introduction to CIGS Thin-Film Photovoltaics

Third Generation Solar Panels

The third-generation solar panels encompass all research that is currently ongoing to improve solar panels. This generation of solar panels is expected to be produced from new and innovative materials such as nanotubes, conductive plastics, and organic dyes.

Conclusion

There are several options to choose from when deciding which material to use for your solar panel. Each option has its merits and demerits which must be considered before a choice is made. If you want to know more about the CIGS and other solar cell coating materials, we’d like to advise you to visit Stanford Advanced Materials (SAM) for more information.