Preparation

It is very important to keep the vacuum chamber clean. Some residues formed during use will collect moisture and other pollutants, directly affecting the success rate of vacuum coating. Short-circuit or target arcing, film-forming surface roughness, and chemical impurities are often exceeded due to unclean sputtering chambers, sputter guns, and targets.

In order to maintain the composition characteristics of the coating, the sputtering gas (argon or oxygen) must also be cleaned and dried. After the substrate is placed in the sputtering chamber, the air needs to be extracted to achieve the vacuum status required by the process.

Dark area shields, cavity walls and adjacent surfaces also need to be kept clean. In the cleaning of the vacuum chamber, we recommend the use of glass ball blasting to remove the dirty parts while using compressed air to remove the spattered residue from the periphery of the cavity, and then gently polishing the surface with alumina-impregnated sandpaper. After the paper is polished, it is washed with alcohol, acetone and deionized water, and an industrial vacuum cleaner is recommended for auxiliary cleaning.

When using the target, wear a protective glove that is clean, and avoid direct contact with the target by hand.

Cleaning

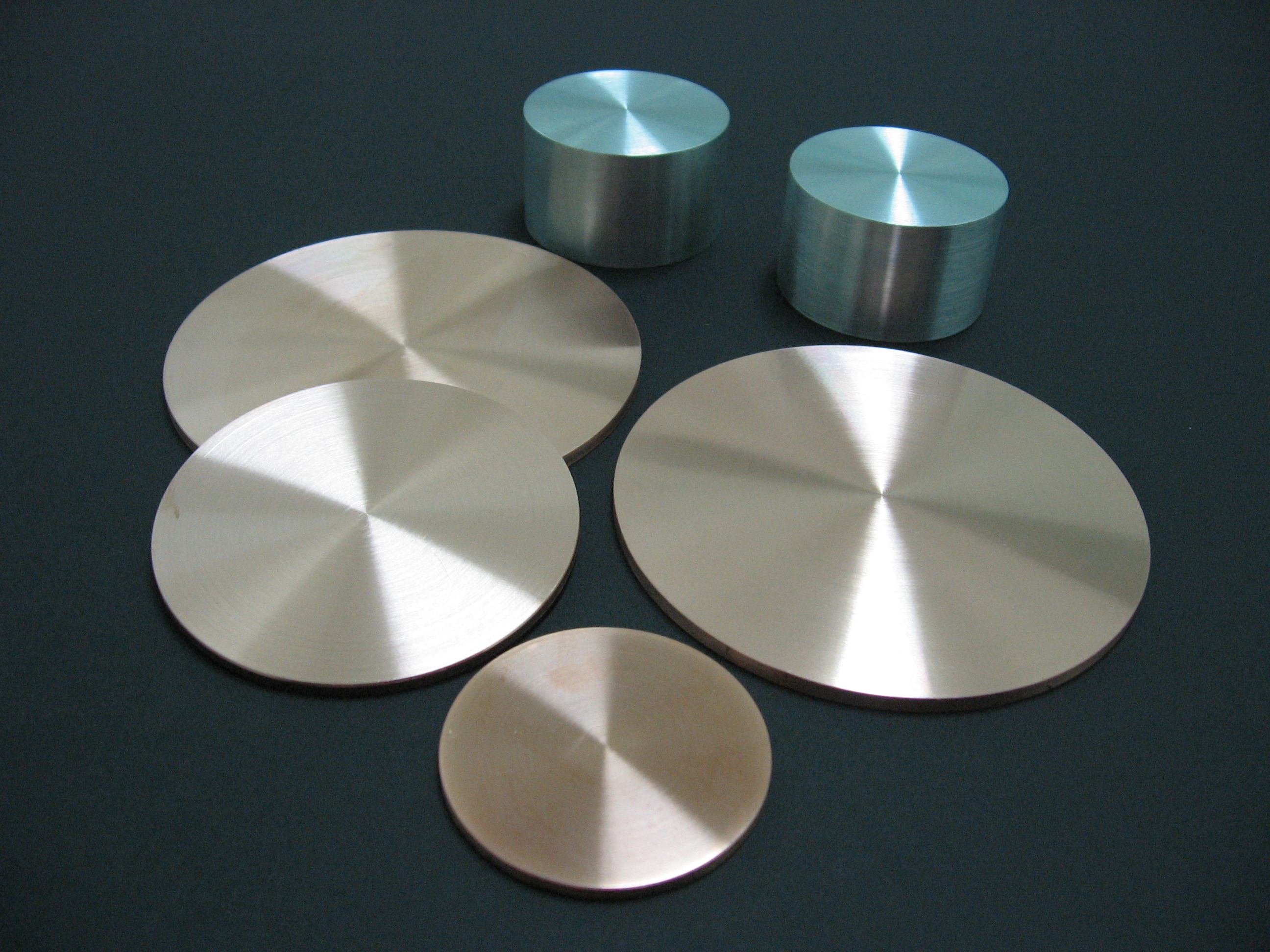

The purpose of target cleaning is to remove the dust or dirt that may be present on the surface of the target. The metal target can be cleaned in the following four steps: the first step is using a soft, lint-free cloth soaked in acetone; the second step is similar to the first step, cleaning with alcohol; the third step is washing with deionized water; the fourth step is placing the target in an oven and drying at 100 degrees Celsius for 30 minutes.

Oxide and ceramic targets are recommended for cleaning with a “lint-free cloth”. After the soiled area has been removed, the target is flushed with high pressure, low moisture argon to remove any contamination particles that may cause arcing in the sputtering system.

Installation

During the target installation, it is important to ensure a good thermal connection between the target and the stabilizing wall of the sputter gun. If the degree of warpage of the stave or backing plate is severe, the thermal conductivity of the back target to the target will be greatly affected, resulting in the heat not being dissipated during the sputtering process, which will eventually cause the target to crack.

Packaging and transportation

All targets should be packaged in a vacuum-sealed plastic bag with a moisture barrier. The outer packaging is generally a wooden box with an anti-collision layer around it to protect the target and the back target from damage during transportation and storage.

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputtering targets such as metals, alloys, oxides, ceramic materials. If you have any questions about sputtering targets, please visit our website https://www.sputtertargets.net for more information.