Introduction

In recent advancements within material science, researchers at the University of Tokyo have made a significant discovery that could revolutionize heat storage technology. This new material, stripe-type-lambda-trititanium-pentoxide (λ-Ti₃O₅), showcases exceptional heat absorption and release properties, making it a game-changer for various industrial applications. Understanding the properties and potential applications of this material can help industries enhance their energy efficiency and thermal management systems.

Discovery of This New Material

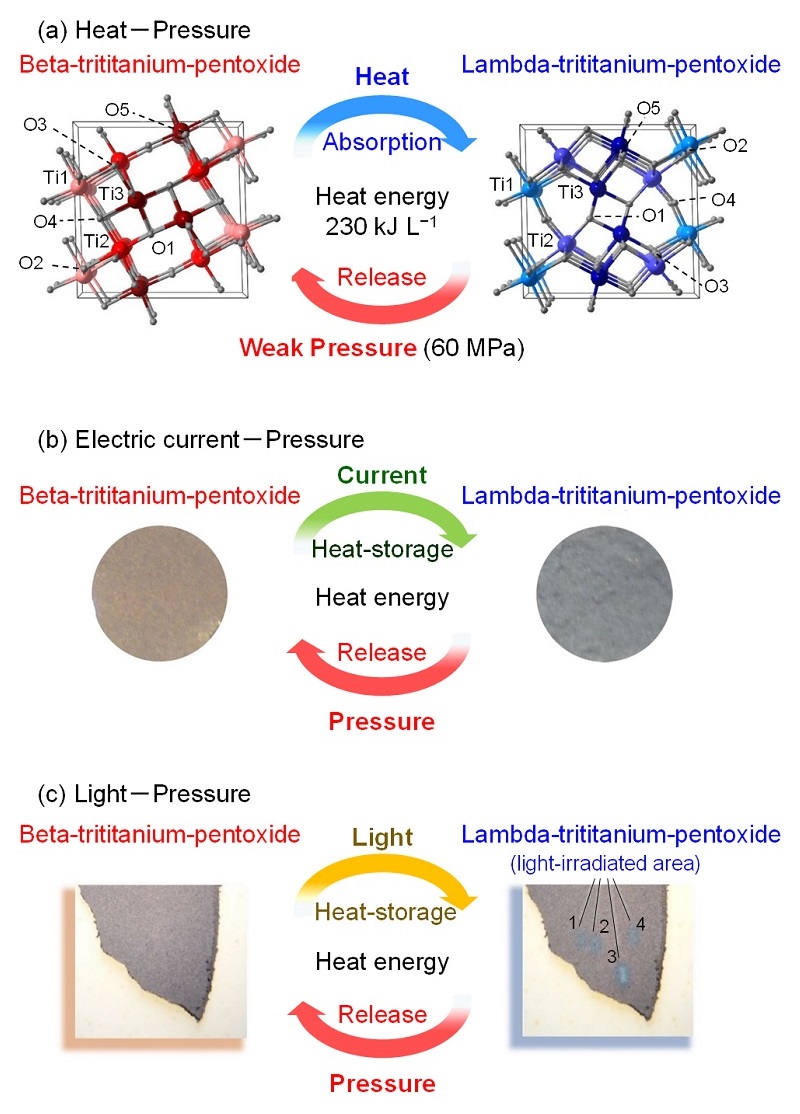

Researchers at the University of Tokyo have unveiled a new type of heat-storage ceramic known as stripe-type-lambda-trititanium-pentoxide (λ-Ti₃O₅). This material is composed exclusively of titanium and oxygen atoms, which allows it to absorb and release a substantial amount of heat energy (230 kJ/L). The unique characteristic of this ceramic is its ability to release stored heat upon the application of a weak pressure of 60 MPa. The research, led by Professor Shin-ichi Ohkoshi, highlights the potential of λ-Ti₃O₅ to transform energy storage and thermal management across various sectors.

The significance of this discovery lies in the material’s efficiency and versatility. λ-Ti₃O₅ can store heat energy not only through direct heating but also by passing an electric current or light irradiation through the material. This makes it highly adaptable for different applications, from industrial heat waste recycling to advanced electronic devices.

Properties and Benefits

The properties of stripe-type-lambda-trititanium-pentoxide make it an exceptional material for heat storage. One of the key benefits is its high heat storage capacity. At 230 kJ/L, the stored heat energy is approximately 70% of the latent heat energy of water at its melting point. This high energy density makes λ-Ti₃O₅ highly efficient for applications where large amounts of heat need to be stored and released on demand.

Another significant property is the material’s ability to undergo a phase transition under relatively low pressure. Applying a pressure of 60 MPa to λ-Ti₃O₅ induces a transition to beta-trititanium-pentoxide, releasing the stored heat energy. This phase transition can be triggered not only by pressure but also by electric current or light irradiation, providing multiple methods for heat management and energy release.

Applications

The unique properties of stripe-type-lambda-trititanium-pentoxide enable a wide range of applications across various industries. Here are some detailed examples:

- Renewable Energy Systems:

- Solar Energy Storage: λ-Ti₃O₅ can be used in solar thermal energy systems to store heat collected during the day and release it during the night or cloudy periods. This enhances the efficiency of solar power plants by providing a reliable thermal energy storage solution.

- Solar Panels: Integrating λ-Ti₃O₅ into solar panels can improve their efficiency by managing thermal loads and preventing overheating, thus prolonging their lifespan and performance.

- Industrial Heat Waste Recycling:

- Manufacturing Processes: Industries that produce significant amounts of heat waste, such as steel or glass manufacturing, can use λ-Ti₃O₅ to capture and store this excess heat. The stored heat can then be reused in other parts of the manufacturing process, reducing overall energy consumption and costs.

- Power Plants: Thermal power plants can benefit from λ-Ti₃O₅ by storing excess heat generated during peak operations and releasing it during lower demand periods, improving the plant’s overall efficiency and reducing fuel consumption.

- Advanced Electronics:

- Heat Management in Devices: λ-Ti₃O₅ can be incorporated into electronic devices to manage heat dissipation more effectively. This is particularly useful for high-performance computing systems and servers where heat management is critical.

- Reusable Heating Pads: The material can be used to develop heating pads that store and release heat on demand, providing a convenient and energy-efficient solution for personal and medical use.

- Sensors and Actuators: Pressure-sensitive and thermally responsive sensors can be developed using λ-Ti₃O₅, enabling more precise control in various applications, including automotive and aerospace industries.

- Construction Materials:

- Building Insulation: Incorporating λ-Ti₃O₅ into building materials can improve the thermal efficiency of buildings. The material can store heat during the day and release it during the night, reducing the need for additional heating and cooling systems.

Relevance to Thin Film Coating

Although stripe-type-lambda-trititanium-pentoxide itself may not be directly used in our products, the principles and properties discovered through this research are closely related to the materials we offer at Stanford Advanced Materials. Our product line, including Titanium Pentoxide Sputtering Target and Trititanium Pentoxide Evaporation Materials, involves advanced materials science techniques that are aligned with the developments seen in λ-Ti₃O₅.

These products can contribute to the creation of thin films with high heat resistance and efficient energy storage capabilities. By understanding and leveraging the underlying science of materials like λ-Ti₃O₅, we can enhance the performance of our thin-film coatings, making them more effective in applications requiring precise thermal management and energy efficiency. This alignment with cutting-edge research ensures that our products remain relevant and highly functional in a rapidly advancing technological landscape.

Future Prospects and Conclusion

The discovery of stripe-type-lambda-trititanium-pentoxide opens new avenues for advancements in heat storage and energy efficiency. The material’s unique properties offer substantial benefits for various industrial applications, from renewable energy systems to advanced electronics. As research continues, we can anticipate further developments that will enhance the performance and applicability of this material.

At SAM, we are committed to staying at the forefront of material science innovations. By integrating insights from cutting-edge research like the discovery of λ-Ti₃O₅, we aim to develop and offer products that meet the evolving needs of our clients. Our focus on quality and technological advancement ensures that we contribute to the progress and efficiency of industries worldwide.

References

- University of Tokyo. (2015). Discovery of a ‘heat-storage ceramic’. Retrieved from University of Tokyo

- Nature Communications. (2015). External Stimulation-Controllable Heat-Storage Ceramics. Retrieved from Nature Communications

- ScienceDaily. (2015). Discovery of a ‘heat-storage ceramic’. Retrieved from ScienceDaily