If you’ve ever wondered about the magic behind the shiny surfaces of electronic devices, solar cells, or even reflective mirrors, you might find the answer in a small but crucial component: the silver sputter target. In this article, we’ll break down the basics of silver targets, exploring what they are, how they work, and the applications that make them indispensable in various industries.

What is a Silver Sputter Target?

A silver (Ag) sputter target is like a silent hero in the world of thin film deposition. Thin films play a significant role in the production of electronic components and devices, and silver sputter targets are a key player in making this happen. Picture it as a special material, typically made of silver, that takes center stage in a process called physical vapor deposition (PVD).

The Sputtering Process Explained

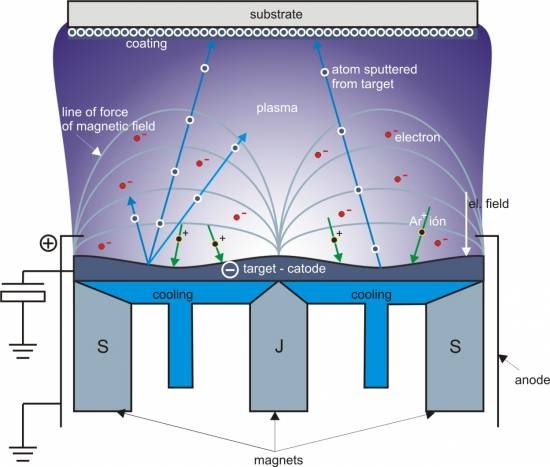

Now, let’s demystify the sputtering process. Imagine you have a silver sputter target in a vacuum chamber. In the PVD process, high-energy ions are thrown at this target, causing silver atoms to be ejected from its surface. These silver atoms then dance through the vacuum and eventually settle on a substrate, which could be a semiconductor wafer, glass, or another material.

Think of it as a painting with tiny silver particles. The sputtering process provides a precise way to deposit thin layers of silver onto a surface, allowing manufacturers to control the thickness and properties of the resulting silver film.

Applications of Silver Sputter Targets

Now that we understand how silver sputter targets work, let’s explore where they make a difference in our everyday lives:

- Electronics: Your smartphone, laptop, or any electronic gadget you use relies on the miniaturized wonders of semiconductors. Silver sputter targets play a crucial role in producing the thin films needed for these semiconductor devices, contributing to their functionality and performance.

- Solar Cells: In the quest for sustainable energy, solar cells harness the power of sunlight to generate electricity. Silver sputter targets come into play in the production of thin films within solar cells, improving their efficiency and enabling the conversion of sunlight into usable energy.

- Optical Coatings: Ever wonder how mirrors maintain their reflective glory? Silver sputter targets are used to create thin films on optical surfaces, ensuring that mirrors and other reflective materials retain their reflective properties.

- Displays: The screens on your television, computer monitor, or smartphone require intricate layers of materials to deliver vibrant and clear images. Silver sputter targets contribute to the production of these thin film layers, enhancing the quality of your visual experience.

Further Reading: Case Study: Silver Evaporation Material Deposition on Glass Surface

Advantages of Silver Sputter Targets

- High Conductivity: Silver is renowned for its excellent electrical conductivity, making it an ideal choice for applications in the electronics industry. The thin films produced using silver sputter targets maintain these conductivity properties.

- Reflectivity: In optical applications, the reflective nature of silver is highly valued. Thin films generated by silver sputter targets ensure that surfaces remain reflective, contributing to the performance of optical devices.

- Controlled Thickness: One of the key benefits of using silver sputter targets is the ability to control the thickness of the deposited film. This precision is vital in manufacturing processes where thin films must meet specific requirements.

Conclusion

In the world of advanced technologies, silver sputter targets might not grab the headlines, but their contribution is undeniably significant. From powering your electronic devices to harnessing solar energy and enhancing the reflective surfaces in your daily life, silver sputter targets play a crucial role.

Next time you marvel at the sleek design of your smartphone or the clarity of your mirror, remember the tiny silver particles that quietly worked behind the scenes, thanks to the remarkable process of sputtering and the unassuming silver sputter targets.